-

-

Key Considerations for Using Tungsten Carbide Parts: What You Need to Know!

In the vast realm of the hardware industry, tungsten carbide parts occupy an indispensable position with their unique properties, widely utilized across various mechanical fields. Today, Yize’s editor will meticulously […]

More

carbide questions and answers

Carbide questions and answers. Grinding, cutting, holes, wheel and more. Machining service for various precision tungsten carbide products. Carbide products inc in China.

-

-

In-Depth Analysis: Tungsten Carbide Parts – The Hardy Pillar of the Industrial Sector

When it comes to Tungsten Carbide materials, many in the industrial machinery sector, especially those who frequently work with them, are well acquainted with their unique attributes. Tungsten Carbide parts […]

More

-

-

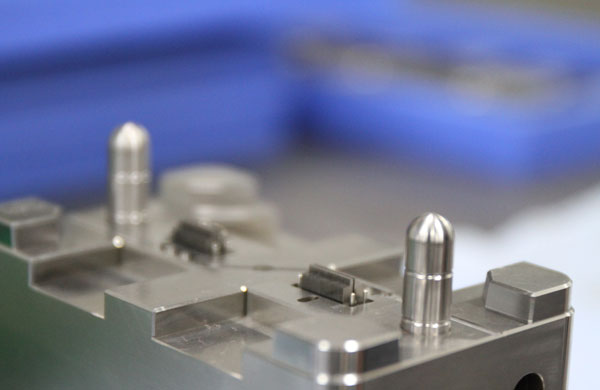

Selecting Tungsten Carbide for Mold Applications

It is not uncommon for customers to inquire, upon first contact, “What is the hardness of your Tungsten Carbide? Do you have anything harder?” However, there exists a common misconception […]

More

-

-

Tungsten Carbide Welding Techniques Unveiled

Tungsten Carbide, renowned for its exceptional hardness and wear resistance, stands out in numerous industrial applications. However, this same hardness presents a challenge during processing. Consequently, in practical production, many […]

More

-

-

Storage Secrets for Finely Polished Tungsten Carbide

Tungsten Carbide, renowned for its high surface finish and precise dimensions, demands meticulous storage. Improper storage can easily tarnish its flawless appearance, compromising product quality. It may be commonly believed […]

More

-

-

Cemented Carbide: Properties, Advantages and Areas of Application

Cemented carbide (also known as tungsten carbide) is a series of composite materials consisting of tungsten carbide particles bonded together by a metallic binder, cobalt (Co). The aggregates are usually […]

More

-

-

Does carbide wear out?

Carbides undergo wear out use, Despite being used as mechanical parts, cutting tools, or mining and drilling tools. Before discussing the wear issues of cemented carbide, it’s essential to understand […]

More

-

-

What is carbide used for?

Carbide can be used as molds, cutting tools, drill bits, in mining operations, oil and gas drilling, aerospace, etc. Common parts include hardware molds (such as wire drawing dies, bolt […]

More

-

-

How is carbide made?

The production of carbide materials primarily involves two methods: powder metallurgy and molten metallurgy. Carbide components are typically manufactured using the former method, shaping them into various forms such as […]

More

-

-

What is carbide wear parts?

Carbide wear parts refer to mechanical components and mold parts made from carbide materials, including drill bits, cutting tools, stamping die parts, stretching dies, cold heading dies, washers, bushings, bearings, […]

More