Exploring Tungsten Carbide

Introduction In the grand stage of modern industry, tungsten carbide is attracting the attention of numerous professionals in various industries with its irreplaceable and significant position. As a cemented carbide, […]

Introduction

In the grand stage of modern industry, tungsten carbide is attracting the attention of numerous professionals in various industries with its irreplaceable and significant position. As a cemented carbide, tungsten carbide boasts a series of excellent properties, such as high hardness, wear resistance, heat resistance, and corrosion resistance. It plays a crucial role in many fields, including cutting tools, mold manufacturing, and oil extraction. Next, let’s delve into the unique charm and outstanding performance of tungsten carbide.

Basic Composition of Tungsten Carbide

The birth of tungsten carbide stems from its unique formula and exquisite craftsmanship. It is mainly composed of tungsten carbide (WC) and a metal binder (such as cobalt (Co), nickel (Ni), etc.), carefully prepared through the powder metallurgy process. Tungsten carbide, as the core hard phase of tungsten carbide, is like a tenacious warrior with significant characteristics such as high hardness, high wear resistance, and high melting point, endowing tungsten carbide with a strong “skeleton”. The metal binder, on the other hand, acts like a gentle bond, tightly binding the tungsten carbide particles together, allowing tungsten carbide to possess a certain degree of toughness and strength while maintaining high hardness. This special combination of rigidity and flexibility makes tungsten carbide stand out among many materials, demonstrating unparalleled performance advantages.

当社の工場事業:超硬部品、金型部品、医療用射出成形金型、精密射出成形金型、テフロンPFA射出成形、PFAチューブ継手。電子メール:[email protected],whatsapp:+8613302615729。

Main Characteristics of Tungsten Carbide

High Hardness: The “Sharp Vanguard” in the Cutting Field

The hardness of tungsten carbide is truly remarkable, usually reaching HRA 85 – 93, equivalent to HRC 69 – 81. Such high hardness makes tungsten carbide a formidable force when manufacturing cutting tools and wear – resistant parts. During the cutting process, tungsten carbide tools can maintain their sharpness for a long time, significantly extending their service life, reducing processing costs, and improving production efficiency. Every precise cut demonstrates the outstanding strength of tungsten carbide’s high hardness.

Wear Resistance: The “Durable Wear – Resistant Guardian”

Wear resistance is another prominent characteristic of tungsten carbide. The high hardness and wear resistance of tungsten carbide allow the material to remain stable in the “battlefield” of friction and wear, like a tenacious guardian. It effectively reduces wear and significantly extends service life. This characteristic gives tungsten carbide a broad application prospect in fields such as manufacturing wear – resistant parts and bearings, making it a trusted wear – resistant material in many industries.

Heat Resistance: The “Steel Warrior” in High – Temperature Environments

Tungsten carbide has good heat resistance and can maintain stable performance in high – temperature “purgatory”. When the temperature rises, most materials may become weak, but the hardness and strength of tungsten carbide do not significantly decrease. It can still maintain good cutting and wear – resistant properties, showing obvious advantages in high – temperature operating environments such as manufacturing oil drilling bits and thermal spray nozzles, and becoming the “steel warrior” in high – temperature fields.

Corrosion Resistance: The “Stable Star” in Harsh Environments

Under the erosion of harsh environments such as acids and alkalis, tungsten carbide can still hold its ground and maintain stable performance. This excellent corrosion resistance makes tungsten carbide an indispensable material in manufacturing corrosion – resistant parts and chemical equipment. At the same time, it can effectively improve the reliability and service life of equipment, providing reliable protection for industrial production and becoming the “stable star” in harsh environments.

Good Toughness: The “All – Rounder” with a Combination of Rigidity and Flexibility

Although tungsten carbide has high hardness and wear resistance, it is not a fragile “porcelain doll”. By adding an appropriate amount of metal binder, tungsten carbide exhibits good toughness. Under the test of impact and vibration, it can avoid fracture or damage, showing a combination of rigidity and flexibility. This good toughness makes tungsten carbide widely used in manufacturing high – precision molds and precision parts, becoming an “all – rounder” in the industrial field.

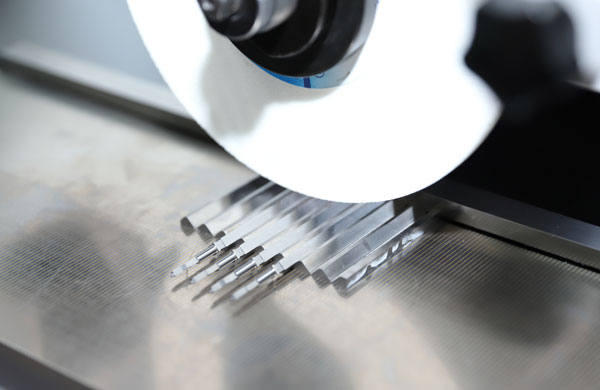

Machinability: The “Versatile Sprite” with High Flexibility

Tungsten carbide material has good machinability. Like a highly flexible “versatile sprite”, it can be easily formed through various processing methods such as cutting, grinding, and welding. This high degree of flexibility and adaptability allows tungsten carbide to meet the diverse needs of different fields and applications during the manufacturing process, bringing more possibilities to industrial production.

Low Magnetism: The “Invisible Guardian” to Avoid Interference

Tungsten carbide has weak magnetism and generally almost no magnetism. This characteristic gives tungsten carbide unique advantages in situations where magnetic field interference needs to be avoided, such as in the manufacturing of electronic devices and medical equipment. At the same time, low magnetism can effectively reduce the magnetization phenomenon during the cutting process, improving cutting accuracy and surface quality, and becoming the “invisible guardian” to avoid magnetic field interference.

Application Fields of Tungsten Carbide

Cutting Tool Field: The “Capable Assistant” for Efficient Machining

In the field of cutting tools, tungsten carbide material is undoubtedly the ideal choice for manufacturing high – speed cutting tools, milling cutters, drills, and other cutting tools. Its high hardness, wear resistance, and good toughness allow tungsten carbide tools to operate efficiently for a long time during the cutting process, with a long service life and high cutting efficiency. Every precise cut is inseparable from the silent contribution of tungsten carbide tools, making it the “capable assistant” for efficient machining.

Mold Manufacturing Field: The “Core Force” for Precision Manufacturing

Tungsten carbide material also plays a crucial role in the field of mold manufacturing. Its high hardness, wear resistance, and good toughness enable tungsten carbide molds to manufacture high – precision, high – requirement parts and products. Whether it’s complex automotive molds or precision electronic molds, tungsten carbide can ensure the high service life and stability of the molds with its outstanding performance, becoming the “core force” for precision manufacturing.

Oil Extraction Field: The “Drilling Pioneer” Deep Underground

In the vast field of oil extraction, tungsten carbide material also demonstrates extraordinary strength. Its high hardness, wear resistance, and heat resistance allow tungsten carbide oil drilling bits to bravely advance in high – temperature, high – pressure, and harsh environments for drilling operations. It is like a “drilling pioneer” deep underground, greatly improving the efficiency and safety of oil extraction and making important contributions to the development of the energy industry.

Other Fields: The “All – Rounder” for Diverse Applications

In addition to the above main fields, tungsten carbide material is also used in many other fields such as machinery manufacturing, metallurgy, and chemical industry. In these fields, tungsten carbide material provides strong support for the manufacturing of various equipment and products with its unique performance advantages, becoming the “all – rounder” for diverse applications.

結論

Tungsten carbide, as a high – performance cemented carbide material, is undoubtedly the “performance champion” in modern industrial fields. Its excellent characteristics such as high hardness, wear resistance, heat resistance, corrosion resistance, good toughness, and low magnetism give it broad application prospects in many fields including cutting tools, mold manufacturing, and oil extraction. By deeply understanding and mastering the characteristics and application fields of tungsten carbide, we can better utilize this high – quality material to inject strong impetus into the development and innovation of the industrial field and promote the continuous advancement of industry to new heights.