Tungsten Carbide: A Shining Star in Modern Industry

Tungsten carbide, this alloy material meticulously crafted from refractory metal hard compounds and binder metals, holds a pivotal position in modern industry thanks to its outstanding physical and chemical properties. […]

Tungsten carbide, this alloy material meticulously crafted from refractory metal hard compounds and binder metals, holds a pivotal position in modern industry thanks to its outstanding physical and chemical properties.

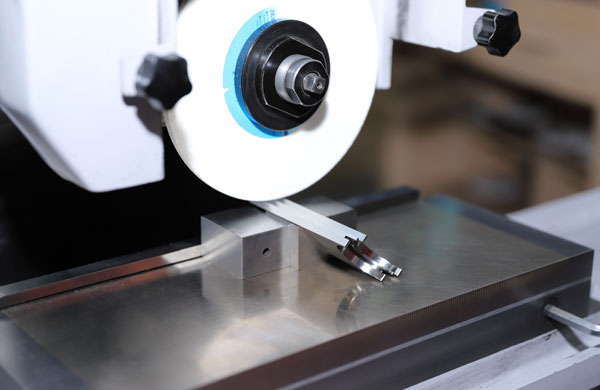

The hardness of tungsten carbide reaches 86–93HRA, far exceeding that of ordinary metallic materials, and its wear resistance is excellent, maintaining its basic properties even at high temperatures. This characteristic makes it the preferred material in high-wear fields such as cutting processing, mining, and oil drilling.

La nostra attività in fabbrica: parti in metallo duro, parti di stampi, stampi a iniezione medicali, stampi a iniezione di precisione, stampaggio a iniezione di teflon PFA, raccordi per tubi PFA. e-mail: [email protected],whatsapp:+8613302615729.

In addition to hardness and wear resistance, tungsten carbide also possesses high strength and toughness. This combination of properties allows it to perform well under impact and vibration, resisting fracture or chipping, thus ensuring the stability of tools during prolonged use.

Tungsten carbide also exhibits good heat and corrosion resistance. Its hot hardness can reach 900–1000°C, maintaining high hardness within this temperature range. Simultaneously, it has strong resistance to corrosive media such as acids and alkalis, enabling it to work stably in harsh environments for extended periods, thus being widely used in industries like chemicals and metallurgy.

In the field of cutting processing, the advantages of tungsten carbide are particularly prominent. Compared with alloy steel tools, it can increase tool life by multiples or even hundreds of times, reducing the frequency of tool changes and downtime. At the same time, it can significantly increase metal cutting speeds and crustal drilling speeds, improving labor productivity and reducing production costs.

Furthermore, tungsten carbide can process difficult-to-machine materials that high-speed steel struggles with, such as heat-resistant alloys and titanium alloys, making it widely applicable in high-end manufacturing fields like aerospace and military industries.

Looking ahead, with technological advancements and industrial development, the application fields of tungsten carbide will continue to expand. The emergence of new tungsten carbide materials will also inject new vitality into its development. Tungsten carbide, this shining star in modern industry, will continue to play a pivotal role.