The Competitive Advantages of Tungsten Carbide Cutting Tools in the Market

In the rapid – developing modern industry, cutting tools, as indispensable instruments in mechanical processing, have a direct impact on production efficiency and product quality. Tungsten carbide cutting tools, with […]

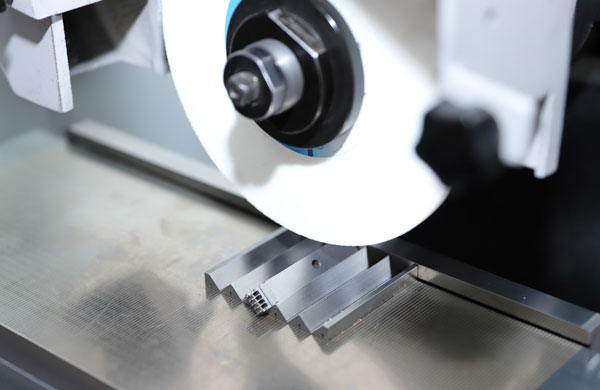

In the rapid – developing modern industry, cutting tools, as indispensable instruments in mechanical processing, have a direct impact on production efficiency and product quality. Tungsten carbide cutting tools, with their unique material characteristics and outstanding performance, occupy an important position in the market. Below, we will analyze the competitive advantages of carburo di tungsteno cutting tools in the market from multiple aspects and summarize them with relevant figures and information.

The Outstanding Material Characteristics of Tungsten Carbide Cutting Tools

Tungsten carbide, also known as hardmetal, is an alloy material made by powder metallurgy from tungsten carbide (WC) and a metal binder (such as cobalt, Co). This material possesses a series of excellent characteristics, such as high hardness, high strength, high wear resistance, and high elastic modulus, which enable tungsten carbide cutting tools to perform exceptionally well in cutting operations.

La nostra attività in fabbrica: parti in metallo duro, parti di stampi, stampi a iniezione medicali, stampi a iniezione di precisione, stampaggio a iniezione di teflon PFA, raccordi per tubi PFA. e-mail: [email protected],whatsapp:+8613302615729.

Ultra – high Hardness

The hardness of tungsten carbide reaches 65 to 70 HRC, a value far exceeding that of ordinary steel. This high hardness allows tungsten carbide cutting tools to easily cut materials of various hardnesses, including some difficult – to – machine high – hardness materials.

Eccellente resistenza all'usura

Due to its high hardness and high wear resistance, tungsten carbide cutting tools can maintain their sharpness for a long time during the cutting process. This reduces the frequency of tool changes and improves production efficiency.

High Strength and Toughness

Tungsten carbide cutting tools not only have high hardness but also good strength and toughness. This makes them less prone to breaking during the cutting process, ensuring the stability and safety of cutting operations.

The Significant Market Competitive Advantages of Tungsten Carbide Cutting Tools

High Cutting Efficiency and Processing Quality

The high hardness and wear resistance of tungsten carbide cutting tools enable them to maintain their sharpness for a long time during the cutting process, thereby improving cutting efficiency. At the same time, tungsten carbide cutting tools have low cutting forces and low cutting heat, which can reduce thermal deformation and surface roughness of the workpiece and improve processing quality.

Wide Range of Application Fields

Thanks to their excellent performance, tungsten carbide cutting tools are widely used in various mechanical processing fields, including the automotive, aerospace, mold, and electronics industries. Whether it is high – precision machining or mass production, tungsten carbide cutting tools can meet different processing needs.

Long Service Life and Low Cost

The good wear resistance of tungsten carbide cutting tools results in a long service life. This reduces the frequency of tool changes and downtime, thereby lowering production costs. Although the initial investment cost of tungsten carbide cutting tools may be relatively high, in the long run, due to their long service life and high efficiency, the overall cost of use is relatively low.

Good Environmental Adaptability

Tungsten carbide cutting tools have excellent heat resistance and can maintain stable cutting performance even in high – temperature environments. In addition, they also have good corrosion resistance and oxidation resistance, allowing them to work stably for a long time in harsh working environments.

Technological Innovation Drives Development

With the continuous progress of science and technology and the continuous innovation of processes, the performance of tungsten carbide cutting tools is also constantly improving. The application of new tungsten carbide materials, coating technologies, and nanotechnologies provides strong technical support for the development of tungsten carbide cutting tools. These technological innovations not only improve the performance of tungsten carbide cutting tools but also expand their application fields.

Conclusione

In summary, tungsten carbide cutting tools demonstrate strong competitive advantages in the market with their excellent material characteristics such as high hardness, high wear resistance, high strength, and high toughness. Whether it is improving cutting efficiency, ensuring processing quality, adapting to diverse applications, reducing costs, or coping with harsh environments, tungsten carbide cutting tools perform outstandingly. With continuous technological innovation, tungsten carbide cutting tools are bound to play an even more important role in modern industry and contribute greater strength to industrial development.