The Versatile Applications of Tungsten Carbide

Tungsten Carbide, also known as cemented carbide, is a high-performance alloy material synthesized through powder metallurgy by combining tungsten carbide with metal powders such as cobalt. Owing to its outstanding […]

Tungsten Carbide, also known as cemented carbide, is a high-performance alloy material synthesized through powder metallurgy by combining tungsten carbide with metal powders such as cobalt. Owing to its outstanding physical and chemical properties, including ultra-high hardness, exceptional strength, remarkable wear resistance, excellent corrosion resistance, and superior red hardness, Tungsten Carbide plays a pivotal role in numerous industries. This article delves into the widespread applications of Tungsten Carbide across various sectors and elucidates its unique advantages.

1. A Vital Tool in Mechanical Processing

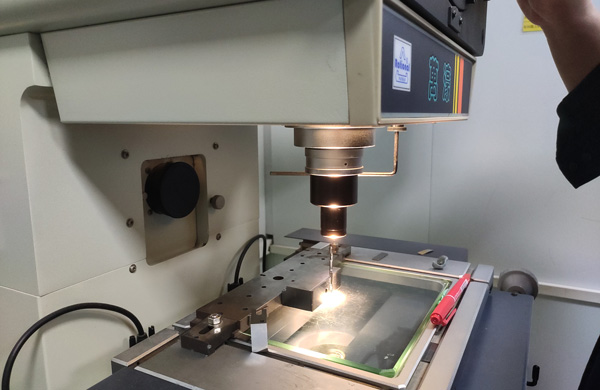

In the mechanical processing industry, Tungsten Carbide is the preferred material for manufacturing cutting tools and knives, including lathe tools, milling cutters, planing tools, drills, and boring tools. These tools, leveraging Tungsten Carbide’s high hardness and wear resistance, can effortlessly cut through various materials such as cast iron, non-ferrous metals, plastics, chemical fibers, graphite, glass, stone, and even ordinary steel. Particularly when processing difficult-to-machine materials like heat-resistant steel, stainless steel, high manganese steel, and tool steel, Tungsten Carbide tools demonstrate unparalleled efficiency and precision, becoming indispensable for high-precision and high-efficiency mechanical processing.

Nuestra actividad de fábrica: piezas de carburo, piezas de molde, moldes de inyección médica, moldes de inyección de precisión, moldeo por inyección de teflón PFA, accesorios de tubo PFA. correo electrónico: [email protected],whatsapp:+8613302615729.

2. The Solid Foundation of Mining and Metallurgy

In the mining and metallurgy industries, Tungsten Carbide, with its exceptional hardness and wear resistance, is widely used in the manufacture of rock drilling tools, mining tools, and drilling tools. These tools shine in mining, oil drilling, and construction projects, significantly enhancing work efficiency while reducing equipment wear and maintenance costs, providing a solid foundation for the industries’ continuous and efficient operation.

3. The Precision Choice for Electronics and Telecommunications

In the electronics and telecommunications industry, Tungsten Carbide, with its high melting point and excellent electrical conductivity, is an ideal material for manufacturing precision electronic components and semiconductor devices. In fine processes such as electronic packaging, welding, and cutting, Tungsten Carbide tools and instruments ensure the outstanding quality and reliability of electronic products through precise machining, driving the continuous advancement of industry technology.

4. The Sturdy Support for the Construction Industry

In the construction industry, Tungsten Carbide is equally widely applied, primarily in the production of cutting tools, drills, and building material processing tools. Its high hardness and wear resistance make building material processing more efficient and of higher quality. Furthermore, Tungsten Carbide’s application in reinforcing reinforced concrete, manufacturing explosion-proof doors, and anti-theft windows greatly enhances building safety and durability, providing solid protection for modern architecture.

5. The Sharp Blade of the Ordnance Industry

In the ordnance industry, Tungsten Carbide, with its high density and hardness, is the preferred material for manufacturing key components of military equipment such as armor-piercing projectiles and anti-tank projectiles. The use of Tungsten Carbide not only significantly enhances the penetrating and destructive power of weapons but also greatly improves their service life and reliability, providing strong support for national defense security.

6. The Reliable Guarantee for Aerospace

In the aerospace field, Tungsten Carbide, with its high-temperature strength and corrosion resistance, is an ideal choice for manufacturing critical components such as aerospace engine parts and spacecraft structural parts. In extreme environments, Tungsten Carbide parts maintain stable performance, ensuring the overall performance and reliability of spacecraft and safeguarding human space exploration missions.

7. The Corrosion-Resistant Pioneer in the Chemical Industry

In the chemical industry, Tungsten Carbide, leveraging its excellent corrosion resistance, plays a crucial role in the manufacture of corrosion-resistant equipment and components. Tungsten Carbide parts such as reactors, pumps, and valves work stably in chemical environments for extended periods, significantly enhancing the reliability and service life of chemical equipment and ensuring the safety and efficiency of chemical production.

8. The Performance Enhancer for the Automotive Industry

In the automotive industry, Tungsten Carbide is widely used in the manufacture of engine parts, cutting tools, and molds. Its high hardness, wear resistance, and high-temperature strength are key factors in improving the quality and durability of automotive components. Especially in engine manufacturing, the widespread application of Tungsten Carbide parts such as piston rings and valve seats significantly enhances engine performance and reliability, injecting strong momentum into the sustained development of the automotive industry.

9. The Mining Tool for the Energy Industry

In the energy industry, Tungsten Carbide’s application in oil drilling equipment and mining tools is equally important. Its wear resistance and high-temperature performance make Tungsten Carbide a star in energy extraction. During oil drilling, Tungsten Carbide drills efficiently break through rocks and formations, improving drilling efficiency and success rates. In mining, Tungsten Carbide mining tools can quickly crush and collect ores, boosting mining efficiency.

10. Widespread Applications in Multiple Fields

Beyond the aforementioned industries, Tungsten Carbide also exhibits extensive application prospects in measurement, wear-resistant parts, nozzles, and other fields. In the measurement field, Tungsten Carbide is used to manufacture measuring tools and precision instruments. In the wear-resistant parts field, Tungsten Carbide parts such as metal molds, cylinder liners, and precision bearings are highly favored. In the nozzle field, Tungsten Carbide is indispensable for high-temperature, high-pressure, and high-speed nozzle tips. These applications not only further expand the uses of Tungsten Carbide but also add infinite possibilities to its market prospects.

In conclusion, Tungsten Carbide, as a high-performance alloy material, plays a pivotal role in multiple industries. With continuous technological advancements and growing market demand, the application fields of Tungsten Carbide will continue to expand. In the future, we have reason to believe that Tungsten Carbide will shine even more brightly in more fields, showcasing its unique charm and value.

Entradas relacionadas

- Un análisis en profundidad de los materiales para punzones de carburo de tungsteno

- Una visión general de las ventajas del producto de Tungsten Steel Pin Gauge Company

- Características únicas del diseño y la aplicación de punzones de carburo de tungsteno

- 8 dimensiones clave para evaluar si el servicio de su fabricante de punzones de carburo de tungsteno es realmente completo