Points for Attention in Purchasing Wear-resistant Tungsten Carbide

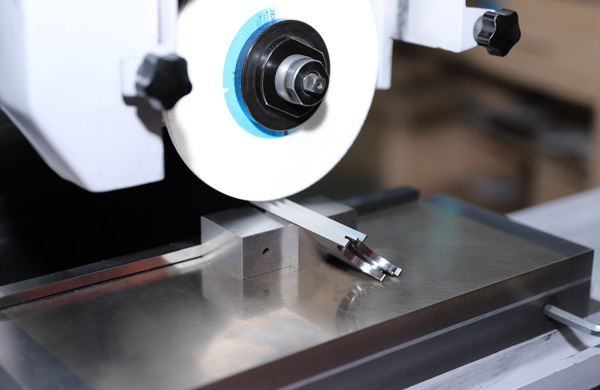

Tungsten carbide, renowned for its exceptional properties, finds wide application in various fields such as cutting tools, mold manufacturing, and wear-resistant parts. However, the market is flooded with a myriad […]

Tungsten carbide, renowned for its exceptional properties, finds wide application in various fields such as cutting tools, mold manufacturing, and wear-resistant parts. However, the market is flooded with a myriad of products, making selection a challenging task. This article aims to provide a comprehensive guide to purchasing tungsten carbide.

Firstly, it’s essential to understand the basics of tungsten carbide, which primarily consists of tungsten carbide (WC) and cobalt (Co), with additional elements added to enhance performance.

Unser Fabrikgeschäft: Hartmetallteile, Formteile, medizinische Spritzgussformen, Präzisionsspritzgussformen, Teflon-PFA-Spritzguss, PFA-Rohrverschraubungen. E-Mail: [email protected],whatsapp:+8613302615729.

Secondly, clarifying usage requirements is crucial. Different scenarios have varying performance demands, necessitating a deep understanding of application needs to make the right choice.

Product quality control is vital. The appearance should be smooth and flawless, with hardness, wear resistance, and toughness all needing professional testing and evaluation.

When choosing suppliers, it’s important to review their qualifications, assess their capabilities, and weigh cost-effectiveness, avoiding blind choices.

Furthermore, ensuring timely delivery and reliable after-sales service is crucial. Clarify delivery times and understand after-sales service policies to guarantee a worry-free purchase.

Additionally, emphasizing environmental protection and sustainable development is also an important consideration in purchasing. Choose products that align with green development concepts to support long-term enterprise growth.

In summary, purchasing tungsten carbide requires comprehensive consideration of multiple factors, from basic understanding and need clarification to quality control, supplier selection, delivery and after-sales, and environmental considerations. Only by considering all aspects can one select high-quality tungsten carbide products that truly meet their needs.