In – depth Analysis: Unveiling the Causes of Tungsten Carbide Product Deformation

Introduction Tungsten carbide, as a high – performance alloy material, plays a crucial role in numerous industries such as machinery manufacturing, electronics, and aerospace, thanks to its high hardness, excellent […]

Introduction

Tungsten carbide, as a high – performance alloy material, plays a crucial role in numerous industries such as machinery manufacturing, electronics, and aerospace, thanks to its high hardness, excellent wear resistance, and remarkable high – temperature resistance. However, during the manufacturing and usage processes of tungsten carbide products, deformation issues often arise. This situation not only has a negative impact on the precision and performance of the products but may also pose potential safety hazards. So, what are the factors that lead to the deformation of tungsten carbide products? The following article will conduct a detailed exploration to help readers gain a deep understanding and effectively prevent such problems.

In – depth Analysis of the Causes of Tungsten Carbide Product Deformation

Carbon Gradient: The “Fuse” of Internal Inhomogeneity

During the dewaxing, presintering, and sintering processes of tungsten carbide, the carbon content in the product changes dynamically, forming a carbon gradient. This carbon gradient is like a hidden “time bomb”. It causes unevenness in the shrinkage of different parts of the tungsten carbide product during the shrinkage process, ultimately leading to deformation and bending. Especially in an H2 sintering atmosphere, if the concentration of CXHY compounds is too high and there is an excessive amount of carbon in the filler, for large products and “long and flat” products, due to the uneven “decarburization” or “carburization” of different parts, the sequence and extent of shrinkage of each part will differ, making product deformation more likely to occur.

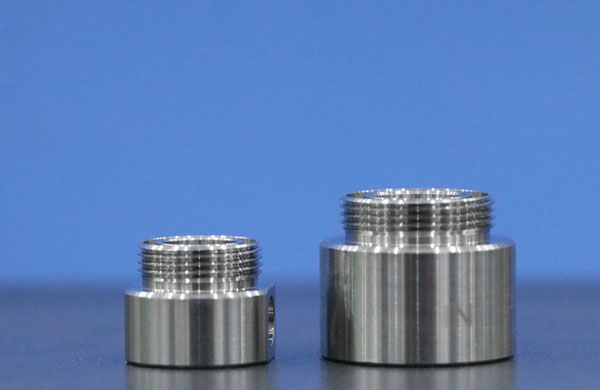

Unser Fabrikgeschäft: Hartmetallteile, Formteile, medizinische Spritzgussformen, Präzisionsspritzgussformen, Teflon-PFA-Spritzguss, PFA-Rohrverschraubungen. E-Mail: [email protected],whatsapp:+8613302615729.

Cobalt Gradient: The “Hidden Hand” Behind the Uneven Distribution

When tungsten carbide undergoes vacuum sintering, the difference in the wettability of cobalt on the surface of the graphite crucible will significantly affect the distribution of cobalt liquid within the product. If the wettability of cobalt on the graphite crucible is poor and the affinity decreases, the cobalt liquid in the product will move upward, causing the surface tension on the upper surface of the product to increase and that on the lower surface to decrease, resulting in the product bulging upward. Conversely, if the wettability of cobalt on the graphite crucible is good and the affinity increases, the cobalt liquid will move downward, increasing the surface tension on the lower surface of the alloy and causing the product to sag downward. The existence of this cobalt gradient is undoubtedly another important cause of tungsten carbide product deformation.

Temperature Gradient: The “Deformation Catalyst” of Thermal Differences

During the manufacturing process of tungsten carbide products, the temperature gradient is also a key factor that triggers deformation. After being heated and melted, cobalt usually flows towards the high – temperature area. That is to say, the cobalt content in the high – temperature part of the product will increase accordingly. The greater the change in the temperature gradient, the larger the gradient of cobalt distribution formed, and the more severe the product deformation will be. This deformation caused by temperature differences is like a “deformation disaster” triggered by heat.

Density Gradient of the Pressed Product: The “Deformation Hidden Danger” of Uneven Pressing

During the pressing process of tungsten carbide, due to factors such as force attenuation, uneven charging, and the complex shape of the product, the bulk density of the mixture will be uneven, forming a density gradient within the tungsten carbide product. The part with a higher density has a smaller shrinkage, while the part with a lower density has a larger shrinkage. This difference will affect the deformation and bending of the product, becoming a potential hidden danger for product deformation.

Improper Boat Loading: The “Deformation Inducement” of Improper Placement

The boat – loading process may seem simple, but it actually has a significant impact on the deformation of tungsten carbide products. If during the boat – loading process, the product is placed in an unreasonable position, has insufficient support, or is not firmly fixed, the product is prone to deformation during the sintering process. This deformation caused by improper boat loading is like a “deformation farce” triggered by improper placement.

Shrinkage Coefficient: The “Deformation Culprit” of Material Differences

Different materials have different shrinkage coefficients. During the manufacturing process of tungsten carbide products, if multiple materials are used and the shrinkage coefficients of these materials differ significantly, deformation may occur during the sintering process due to the inconsistent shrinkage of each material. This deformation caused by the difference in material shrinkage coefficients is the “deformation culprit” brought about by the inherent characteristics of the materials.

Overuse and External Environmental Factors: The “Deformation Pusher” in the Usage Process

In addition to various factors during the manufacturing process, tungsten carbide products may also deform due to overuse or the influence of external environmental factors (such as high temperature and humidity) during the usage process. Overuse can cause the product to reach or exceed its bearable limit, while high temperature and humidity and other environmental factors may change the physical and chemical properties of the product, leading to deformation. This deformation during the usage process is like a “deformation tragedy” caused by the combined effects of time and the environment.

Schlussfolgerung

In summary, the causes of tungsten carbide product deformation are complex and diverse, covering factors during the manufacturing process such as the carbon gradient, cobalt gradient, temperature gradient, density gradient of the pressed product, improper boat loading, and shrinkage coefficient, as well as factors during the usage process such as overuse and external environmental factors. To effectively prevent and reduce the deformation of tungsten carbide products, we need to take comprehensive measures from multiple aspects, optimize the manufacturing process, strictly control product quality, and use and maintain the products reasonably. Only in this way can we ensure that tungsten carbide products can exert their best performance and effects in various fields and provide strong support for the development of different industries.