Carbide stamping die parts

Low-priced China manufacturer buy custom carbide stamping die components, Die punching needle, Bottom punch, die accessories. High quality, fast delivery.

- Info

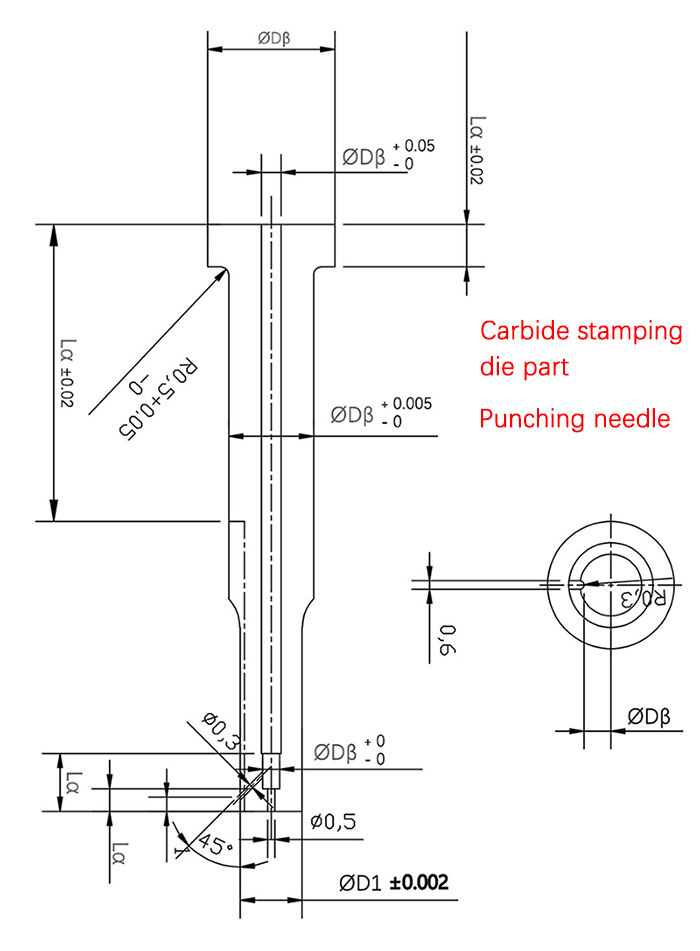

The manufacturing case of carbide stamping die part round punch.

This carbide stamping die part has gone through the following manufacturing processes; punching machine-fine hole-slow wire-discharging

Processing challenges:

- The height is ±0.002mm

- The diameter of the top is small, 0.5mm

- The tolerance of the middle part requires unilateral +0.005mm.

How can we be of assistance to you?

Yize Mold Co., Ltd. processes carbide stamping die parts with a tolerance of 0.02mm-0.002mm. The minimum machining diameter at the top is 0.1mm, and the concentricity and parallelism can be guaranteed to be ±0.002mm.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

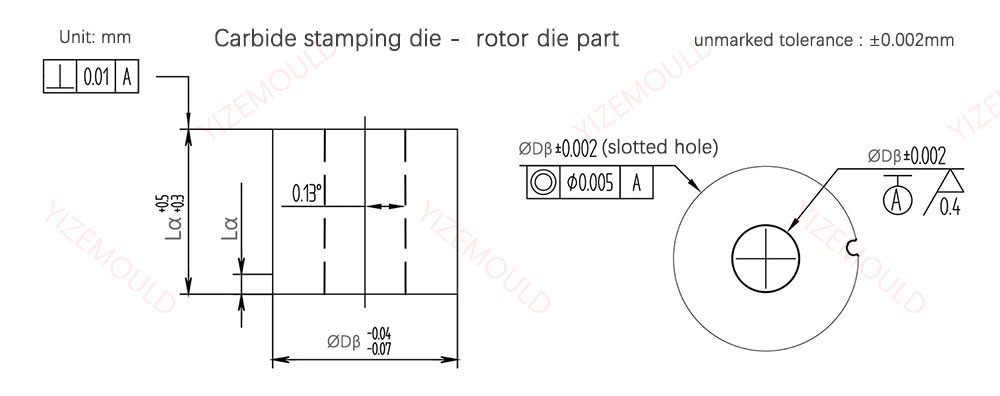

The picture below shows the Carbide stamping die – rotor die part.

The Carbide stamping die uses the following processing technology: Internal and external grinding – Carbide surface grinder.

Processing challenges:

High tolerance requirement of ±0.002mm, and a concentricity tolerance requirement of Ø0.005mm.

What can we offer to support you?

Usually, rotor die and stator die have higher precision requirements, such as the following circular parts, our company can usually achieve the tolerance requirements of ±0.002mm, and the concentricity of ±0.002mm, the circular runout of ±0.002mm and ±0.002mm coaxially.

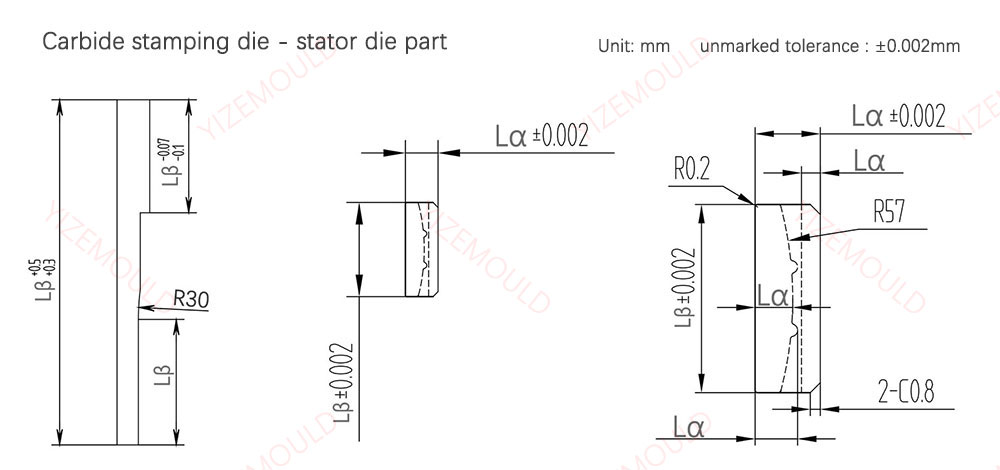

The picture below shows the parts of Carbide stamping die – stator die part.

The following processing technology is used:

Carbide surface grinder – PG

What can we do to help?

Has a high requirement for the tolerance of the size ±0.002mm, and the shape is relatively complicated. There are multiple Rs that need to be processed. The R part uses PG for processing.

Yize Mold is a professional manufacturer of Carbide stamping die parts, which can process precision Carbide stamping die parts of various shapes. There are many experienced processing masters and advanced production equipment, from CNC, Carbide surface grinder, internal and external, EDM, WEDM, and polishing, all are completed independently in-house.

Don’t hesitate to reach out to us if you need any assistance!

Related articles: