Understanding CNC Milling: Materials, Process and Advantages

What Kinds of Materials Can Be CNC Milled? While potentially any solid, stable material can be milled, we have a standard selection of raw materials including hard plastics and aluminum, […]

What Kinds of Materials Can Be CNC Milled?

While potentially any solid, stable material can be milled, we have a standard selection of raw materials including hard plastics and aluminum, various steels, brass, copper, and other alloys. Note that some hardened steels may be too hard for CNC machines or require specialty cutting tools and longer processing times. Soft elastomer plastics may also be impossible to mill since they cannot be held in a fixed position or would change shape under the pressure of the cutting tool.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

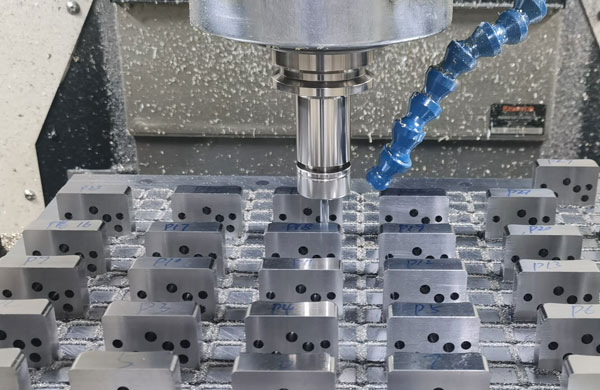

How Does CNC Milling Work?

Today, CNC milling machines are available in vertical and horizontal models, which feature different operations and components, as well as a few similar pieces of hardware:

- Cutter: Shapes the product.

- Spindle: Rotates the chuck across multiple axes.

- Chuck: Locks your material in place for machining.

- Interface: Reads computer-aided design (CAD) or computer-aided manufacturing (CAM) files and controls the milling machine with operator input.

Operations of CNC milling centers adhere to a few core steps, including:

- Input CAD or CAM document

- Install machining material and appropriate cutter

- Launch milling operation via the interface

- Inspect product quality post-machining

While shaping a material into a product, the spindle will move across the Z, Y, and X axes. A five-axis milling center will cross other axes.

Advantages of CNC Milling

Like other types of computer numerical controls for machining applications, CNC milling offers several benefits, including:

- Accuracy: Whether you’re producing an initial prototype or final product, you can trust the item will match the measurements dictated in your CAD or CAM file. That level of precision gives you several advantages, including improved productivity and lowered material waste. It also maximizes your costs for machining the hardware.

- Versatility: The availability of vertical and horizontal CNC milling machines, as well as CNC milling centers in multiple axes, offers excellent versatility. As a result, they can handle projects with varying complexities and parameters with precision.

- Reproducibility: No matter how you’re applying CNC, whether for turning, lathing, or drilling, you can count on the machines to produce your product per your CAD or CAM file every time. That leads to benefits similar to those offered by the accuracy of CNC milling centers, such as decreased waste and increased efficiency.

How to Get a Quote

If you want to get a quote from us, you can send us your CAD files to [email protected] or WhatsApp +86 13302615729. Indicate the quantity, material, finishing, etc. We will get back to you within 24 hours.