Position > > BLOG

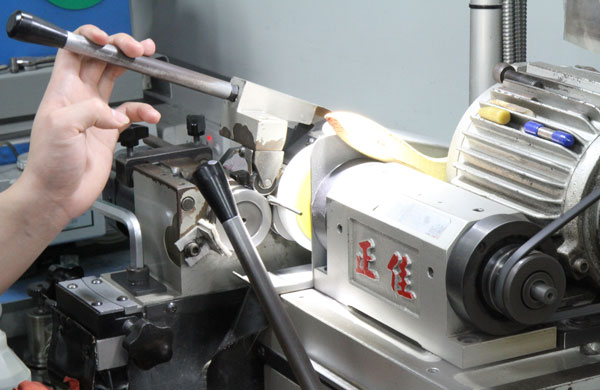

Tungsten Carbide Wire EDM Methods

September 13, 2024

view: 77

When performing wire EDM on Tungsten Carbide, several key points must be kept in mind: Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA […]

When performing wire EDM on Tungsten Carbide, several key points must be kept in mind:

- Control the Current Intensity: Given that Tungsten Carbide is formed through powder molding, with molecules compressed and sintered together, excessive current can lead to the release of energy under external force, resulting in cracking of the Tungsten Carbide. Larger pieces, due to higher internal pressures, are more prone to such issues.

- Avoid Single-Pass Cutting: Owing to Tungsten Carbide’s high density, attempting to cut through an entire piece in one pass often leads to surface damage, which is mistakenly attributed to inherent cracks in the material by many.

- Handle Mirrored Surfaces with Care: For products that have already achieved a mirrored finish, it is advisable to avoid high-speed Wire EDM. Tungsten Carbide, primarily composed of tungsten carbide and cobalt, is susceptible to corrosion by acidic liquids, which can result in the formation of pits that may be mistaken for sand holes in the material.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.