Tungsten Carbide Thread Machining

Cheap factory. Tungsten carbide thread machining can be divided into internal threading and external threading. Internal threads can be achieved through EDM (Electrical Discharge Machining) with a minimum diameter of 1.5mm or M2 thread, with a tolerance controlled within 0.01mm.

Tungsten carbide thread machining can be divided into internal threading and external threading. Internal threads can be achieved through EDM (Electrical Discharge Machining) with a minimum diameter of 1.5mm or M2 thread, with a tolerance controlled within 0.01mm. High-precision external threads of hard alloy are processed using precision grinding machines. Generally, thread machining does not require high precision, except for the forming surfaces of products where higher precision is needed, such as thread joints for water pipes or cosmetic bottle threads.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

1. Milling machines are used for thread cutting in tungsten carbide holes. This method can produce larger internal threads, and external threads are easy to machine.

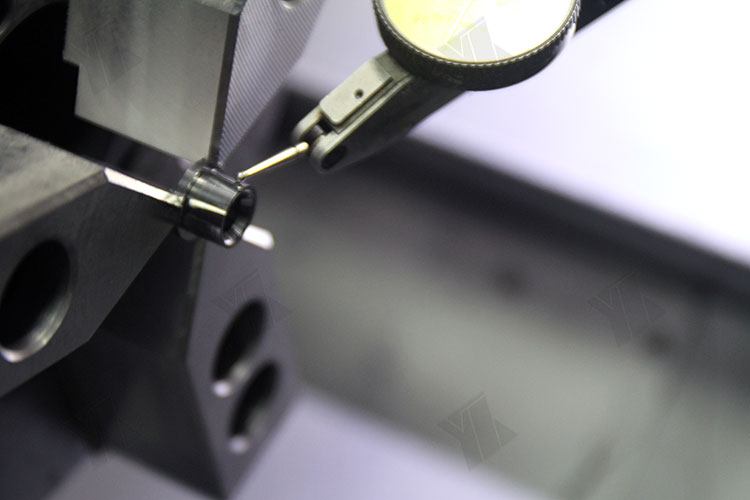

2. Grinding machines are used with grinding wheels for precision grinding of internal threads. This method provides high precision and a smoother finish. In mold factories, grinding machines are commonly used to achieve the highest precision in external thread machining.

3. EDM (Electrical Discharge Machining) is used to create internal threads by erosion without cutting forces. This method is suitable for tungsten carbide and is used for small threads requiring high precision. However, it is a costly process.

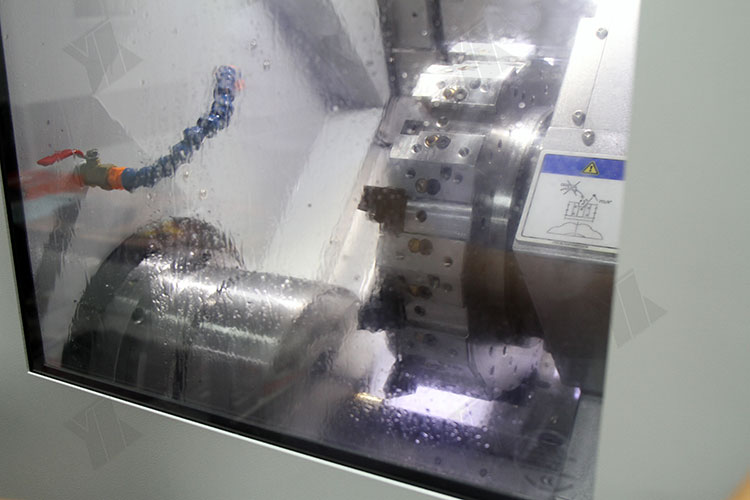

4. CNC (Computer Numerical Control) turning is another method used for thread machining. While the precision is generally average, it offers high efficiency. However, it may not be suitable for machining small-sized internal threads.

Therefore, the appropriate internal thread machining technique should be chosen based on the type of internal thread, precision requirements, efficiency demands, and the material being processed. Detailed evaluation should be conducted based on the specific drawings. Yize Mold provides comprehensive machining services for tungsten carbide components, with various equipment, experienced technicians, and well-established inspection devices and processes. Feel free to contact us for more information.

SAUL SALAS VAZQUEZ:

April 12, 2024Me puede cotizar 3 roscas en material CARBURO, LAS ROSCAS SON 1/4-20 X 1 PULGADA DE LARGO.