Tungsten Carbide Pin Gauges: Precision Manufacturing at Its Finest

As a leading manufacturer of tungsten carbide pin gauges, we have always focused on the meticulous craftsmanship of high-precision products, striving for excellence in every aspect of the process. Our […]

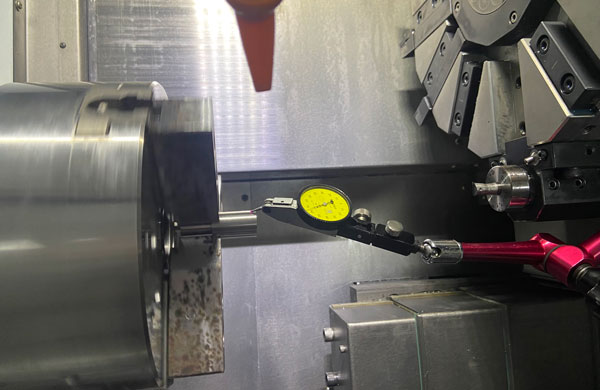

As a leading manufacturer of tungsten carbide pin gauges, we have always focused on the meticulous craftsmanship of high-precision products, striving for excellence in every aspect of the process. Our tungsten carbide pin gauges, crafted from ultrafine particulate tungsten carbide material, boast exceptional hardness, bending strength, and remarkable wear resistance, making them highly resistant to chipping, breaking, and suitable for a wide range of applications including wear-resistant parts, tungsten carbide punches, inserts, powder metallurgy molds, and magnetic material molds. These are precision products with high hardness, made from materials such as white steel, tool steel, ceramics, tungsten carbide bearing steel, and others, tailored to specific dimensions.

In the field of mechanical and electronic processing, our tungsten carbide pin gauges stand out for their precise measurement capabilities, particularly in measuring hole diameters, hole spacings, internal thread diameters, and complex curved slot widths, as well as mold dimensions. Whether it’s for measuring hole sizes, checking distances between two holes, determining hole depths, or serving as go/no-go gauges, they are indispensable tools for standardized hole inspection. We employ internationally advanced inspection equipment to ensure that each product meets the most stringent quality standards.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: info@yizemould.com,whatsapp:+8613302615729.

Product Features & Classification:

- Materials & Processes: Our tungsten carbide pin gauges are available in both extruded and molded forms. The extruded type features a beautiful appearance and is easy to grind, while the molded type offers more uniform density but is slightly more challenging to grind.

- Specification Range: We offer a wide array of sizes ranging from 0.2×5mm to 1.2×5mm to cater to diverse application needs.

- Professional Applications: Specially designed abrasives are suitable for grinding equipment, effectively polishing metal part surfaces, and removing burrs in tight corners. Sizes range from 0.2 to 1.2MM in diameter, with lengths of 5MM and 10MM, all made from Japanese imported 304 stainless steel, offering exceptional value for money.

Usage & Maintenance Guidelines:

- Storage Recommendations: To ensure optimal performance, please clean and dry the tungsten carbide pin gauges before and after use.

- Durability Tips: As semi-permanent consumables, tungsten carbide pin gauges can be used multiple times. Handle with care during operation to avoid damage.

- Polishing Force Adjustment: The thickness of the pin gauge directly impacts the polishing effect. Thicker pins provide stronger polishing force, and the polishing intensity can be finely controlled by adjusting the frequency of the polishing machine.

- Material Selection Guide: Choose the appropriate pin gauge based on the material of the part being processed. For harder materials like stainless steel and iron, pins with a diameter of Φ0.5 or above are recommended, while for softer materials like copper and aluminum, pins below Φ0.5 are preferable. Typically, 5mm long pin gauges are the first choice for polishing.

With our exquisite craftsmanship, rigorous quality control, and deep understanding of customer needs, we continuously drive innovation and development in tungsten carbide pin gauge technology, committed to providing each customer with products and services that exceed expectations.