Tungsten Carbide Parts: The High-Performance Choice in Industrial Manufacturing

In modern industrial manufacturing, the demand for high-precision and wear-resistant parts is on the rise. Tungsten carbide parts stand out with their exceptional performance. This article outlines the characteristics, advantages, […]

In modern industrial manufacturing, the demand for high-precision and wear-resistant parts is on the rise. Tungsten carbide parts stand out with their exceptional performance. This article outlines the characteristics, advantages, applications, and manufacturing processes of tungsten carbide parts.

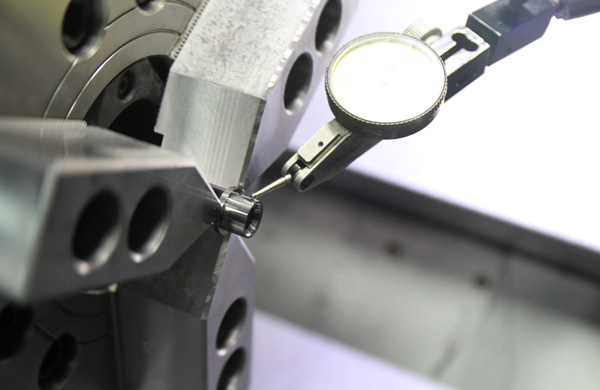

Tungsten carbide parts, with tungsten carbide and metal binders as their core, boast high hardness, wear resistance, thermal stability, and corrosion resistance. Their hardness is second only to diamonds, enabling them to maintain stability under high loads, while their corrosion resistance makes them suitable for harsh environments.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

The advantages of tungsten carbide parts are significant: they improve product quality, extend service life, enhance production efficiency, and reduce costs. Their wear resistance ensures precision and stability over long-term use, while their corrosion resistance enhances durability. The high machinability of these parts further boosts production efficiency and lowers costs.

Tungsten carbide parts find wide application in cutting tools, mold manufacturing, oil drilling, aerospace, and precision machinery manufacturing. They exhibit excellent performance in high-temperature, high-pressure, and corrosive environments.

In terms of manufacturing processes, powder metallurgy is the mainstream method, ensuring high quality through precise control of raw materials and processes. Heat treatment techniques further enhance their performance.

In summary, tungsten carbide parts, with their unique properties and wide applications, are the high-performance choice in industrial manufacturing. As technology advances, tungsten carbide parts will continue to play a pivotal role in more fields, driving industrial manufacturing to new heights.