Tungsten Carbide Molds: A Star in the Mold Industry

Tungsten carbide molds, as a leading force in the mold industry, occupy an important position in precision mold manufacturing due to their high hardness, wear resistance, thermal stability, and corrosion […]

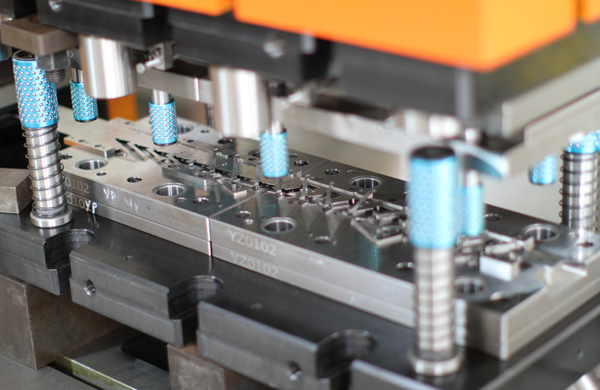

Tungsten carbide molds, as a leading force in the mold industry, occupy an important position in precision mold manufacturing due to their high hardness, wear resistance, thermal stability, and corrosion resistance. Their material is mainly composed of tungsten carbide particles and metal binders, making them both hard and easy to process. The manufacturing process covers key links such as material preparation, mold design, manufacturing, assembly, debugging, and mold testing, ensuring the precision and performance of the molds.

In multiple industries including plastics, die-casting, precision machinery manufacturing, and electronics, tungsten carbide molds demonstrate extraordinary capabilities. Their high precision and stability, long service life, and high production efficiency bring significant economic benefits to enterprises. At the same time, tungsten carbide molds also offer cost-saving advantages, reducing replacement and maintenance costs, as well as scrap rates and rework rates.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Looking ahead, tungsten carbide molds will keep pace with technological development, continuously optimizing production processes, reducing energy consumption, and minimizing pollution to achieve green manufacturing. Additionally, the integration of new materials and technologies will bring new development opportunities for tungsten carbide molds, driving their application and innovation in a wider range of fields. Tungsten carbide molds, with their exceptional performance and wide application, are sure to continue writing a glorious chapter in the mold industry.