Tungsten Carbide Materials: Characteristics, Advantages, and Comprehensive Applications Analysis

Tungsten carbide, an alloy material with exceptional physical and chemical properties, plays a pivotal role in the industrial sector. Renowned for its high hardness, strength, outstanding wear resistance, corrosion resistance, […]

Tungsten carbide, an alloy material with exceptional physical and chemical properties, plays a pivotal role in the industrial sector. Renowned for its high hardness, strength, outstanding wear resistance, corrosion resistance, and excellent red hardness, it maintains superb performance under various harsh conditions. This article aims to provide readers with a comprehensive and in-depth analysis of tungsten carbide’s composition, performance characteristics, and wide-ranging applications.

I. Composition of Tungsten Carbide

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Tungsten carbide, scientifically known as cemented carbide, is precision-fused through powder metallurgy techniques using tungsten carbide (WC) and metal powders such as cobalt (Co). Tungsten carbide, as the core hard phase, endows the material with unparalleled hardness and wear resistance; while cobalt acts as a binder, ensuring tight bonding of the tungsten carbide particles, thereby enhancing the overall strength and toughness of the material. Furthermore, the addition of elements such as nickel, molybdenum, and chromium can further optimize the comprehensive performance of tungsten carbide.

II. Performance Advantages of Tungsten Carbide

- Extreme Hardness: Tungsten carbide’s hardness is second only to diamond, typically ranging from 82.0 to 93.6 HRA (equivalent to 69 to 81 HRC), making it a standout in cutting and grinding operations with sharp and durable edges.

- High Strength: Tungsten carbide can withstand immense impact and pressure, demonstrating excellent resistance to deformation and fracture, suitable for various high-strength applications.

- Corrosion Resistance: In acidic, alkaline, and other corrosive environments, tungsten carbide remains stable, providing reliable solutions for the chemical and petroleum industries.

- Outstanding Red Hardness: Even at high temperatures (up to 900 to 1000°C), tungsten carbide maintains high hardness and rigidity, making it an ideal choice for high-temperature operations.

- Excellent Wear Resistance: Tungsten carbide excels in processing hard materials such as stainless steel and cast iron, making it the preferred material for manufacturing high-precision and high-wear-resistance components.

III. Wide Applications of Tungsten Carbide

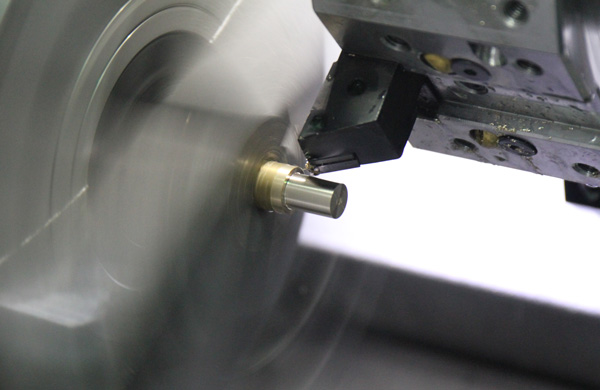

- Mechanical Processing: Tungsten carbide tools such as turning tools, milling cutters, and planing tools shine in the metal processing industry due to their high hardness and wear resistance.

- Mining and Metallurgy: In harsh mining and metallurgical environments, tungsten carbide drilling and mining tools have earned widespread praise for their durability.

- Electronics and Telecommunications: Tungsten carbide’s high melting point and electrical conductivity make it an ideal material for manufacturing precision electronic components and semiconductor devices.

- Construction Industry: In the construction sector, tungsten carbide is used to reinforce structures and manufacture explosion-proof doors, enhancing building safety and durability.

- Aerospace: Tungsten carbide maintains stable performance under extreme conditions, making it widely used in aerospace engine components, spacecraft structural parts, and other critical applications.

IV. Conclusion

Tungsten carbide materials, with their unique performance advantages, exhibit irreplaceable value across multiple industries. As technology advances and industry develops, the application prospects for tungsten carbide will become even broader. We have reason to believe that in the future, tungsten carbide will continue to showcase its unique charm in more fields, contributing further to human technological progress and industrial development.