Tungsten Carbide: A Premier Hard Alloy Material with Wide Applications

Tungsten carbide, as a material with excellent physical and chemical properties, plays a pivotal role in numerous industries. Its high hardness, high strength, wear resistance, corrosion resistance, and high-temperature resistance […]

Tungsten carbide, as a material with excellent physical and chemical properties, plays a pivotal role in numerous industries. Its high hardness, high strength, wear resistance, corrosion resistance, and high-temperature resistance make it an indispensable material in modern industry.

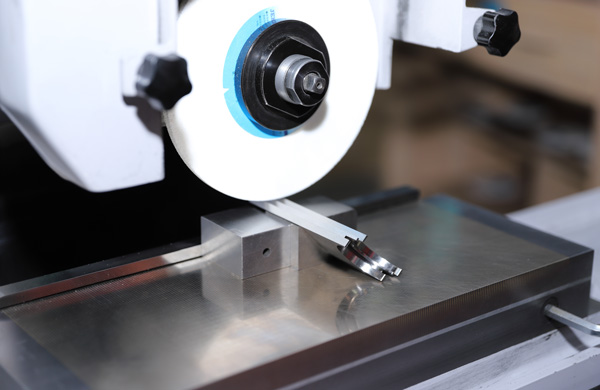

In the machinery manufacturing sector, tungsten carbide is particularly widely used. It is not only the ideal choice for manufacturing cutting tools such as saw blades, milling cutters, and drills, but is also widely applied in mold manufacturing, such as stamping dies and injection molds, significantly improving the service life and processing accuracy of molds. In addition, tungsten carbide bearings are widely used in automobiles, aerospace, precision instruments, and other fields, providing stable and reliable support for high-precision, high-load equipment.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

In the construction industry, tungsten carbide is mainly used for reinforcing reinforced concrete structures and manufacturing explosion-proof doors, anti-theft windows, and other building materials, enhancing the safety and durability of buildings. In the energy industry, such as oil drilling and mining excavation, tungsten carbide tools can work stably for a long time under extreme conditions, effectively improving drilling and excavation efficiency.

The chemical industry has high requirements for corrosion resistance of equipment, and tungsten carbide, with its excellent corrosion resistance, is widely used in the manufacture of corrosion-resistant equipment and components, such as reactors, pumps, valves, etc. In the aerospace industry, the high strength, high hardness, and high-temperature resistance of tungsten carbide make it a material for manufacturing high-precision components such as aerospace engine parts and spacecraft structural parts.

In the electronics and telecommunications field, the high hardness, high density, and good electrical conductivity of tungsten carbide make it an ideal choice for manufacturing precision electronic components and semiconductor devices. In the medical device field, tungsten carbide is widely used in the manufacture of surgical instruments, orthopedic devices, and dental tools due to its wear resistance, high-temperature resistance, corrosion resistance, and radiation protection properties.

In summary, tungsten carbide has a wide range of applications and its prospects will become even broader.