Tungsten Carbide: A Comprehensive Overview of High-Performance Cemented Carbide

In the vast stage of modern industry, the selection and application of materials are as important as the foundation, directly related to the performance, lifespan, and production efficiency of products. […]

In the vast stage of modern industry, the selection and application of materials are as important as the foundation, directly related to the performance, lifespan, and production efficiency of products. Tungsten carbide, a high-performance cemented carbide material, plays an indispensable role in numerous fields due to its unique physical and chemical properties. This article will delve into the mysteries of tungsten carbide, providing a comprehensive overview of its definition, properties, composition and structure, wide range of applications, and forming processes. Additionally, it will analyze the current development status and challenges of China’s tungsten carbide industry and propose corresponding suggestions.

1. Definition and Outstanding Properties of Tungsten Carbide

Tungsten carbide, also known as cemented carbide, is a sintered composite material with refractory metal tungsten carbide (WC) as the hard phase and metals such as cobalt (Co), nickel (Ni), or iron (Fe) as the binder phase. Its hardness reaches up to 69-81 HRC, far exceeding that of ordinary steels, and even at high temperatures, its hardness and rigidity remain stable, making it resistant to softening and deformation. Furthermore, tungsten carbide exhibits excellent corrosion resistance and toughness, enabling it to withstand prolonged use in harsh environments such as acids and alkalis.

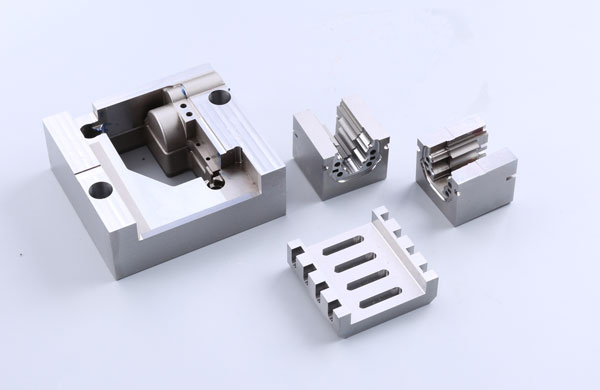

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

2. Composition and Unique Structure of Tungsten Carbide

The core components of tungsten carbide include tungsten carbide and metal binder phases. As the hard phase, tungsten carbide has finely controlled grain sizes ranging from 0.2 to 10 micrometers, tightly bonded together by the metal binder phase, giving tungsten carbide extremely high hardness along with certain toughness and impact resistance. Depending on specific application requirements, elements such as molybdenum and chromium can be added to further optimize its performance and meet diverse needs.

3. Wide Range of Applications for Tungsten Carbide

The outstanding properties of tungsten carbide make it shine in numerous fields. In the cutting tool industry, tungsten carbide tools are the preferred choice for processing steels, forged steels, and other materials due to their high hardness, wear resistance, and heat resistance. In the aerospace industry, tungsten carbide is used to manufacture critical components of aircraft engines owing to its high strength and stability at high temperatures. Simultaneously, tungsten carbide demonstrates extensive application potential in fields such as automotive parts, electronic devices, wear-resistant parts, and metal molds, with its presence evident in components like engine piston rings and electrode needles.

4. Diverse Forming Processes of Tungsten Carbide

The forming processes of tungsten carbide are diverse, with powder metallurgy being the most commonly used. This process mixes tungsten powder with other alloy powders uniformly, followed by pressing, sintering, and other steps to produce tungsten carbide components, offering low costs, high efficiency, and stable performance. Hot extrusion forming is suitable for producing products with complex shapes and high dimensional accuracy; isostatic pressing can produce high-precision products but at a higher cost. Additionally, plasma laser melting and electron beam melting utilize high-energy beams for melting and forming, making them suitable for the production of high-precision, high-performance products. Precision casting is applicable for the manufacture of large and complex tungsten carbide products.

5. Development and Challenges of China’s Tungsten Carbide Industry

With the vigorous development of China’s economy and the transformation and upgrading of its manufacturing industry, the demand for high-performance materials such as tungsten carbide is increasing. However, China’s tungsten carbide industry still faces challenges such as small enterprise scale, low industrial concentration, inefficient resource utilization, and severe environmental pollution. Simultaneously, insufficient technological investment, a shortage of high-end technical talent, and a lack of original core technological achievements also constrain the industry’s development. Therefore, it is imperative to increase technological innovation efforts, improve product quality and added value, strengthen industrial integration, and enhance environmental protection governance.

6. Conclusion and Outlook

Tungsten carbide, as a high-performance cemented carbide material, demonstrates broad application prospects in modern industrial fields. This article provides a comprehensive overview of tungsten carbide from multiple aspects and analyzes the current development status and challenges of China’s tungsten carbide industry. Looking ahead, with the continuous advancement of technology and the ongoing upgrading of industries, it is believed that tungsten carbide will play an even greater role in more fields, contributing to the development of modern industry.