Differences between tungsten and tungsten carbide

Tungsten and tungsten carbide are two distinct substances with unique applications and properties. Tungsten is typically used in lighting equipment, electronic devices, and as electrodes and leads in semiconductor devices. […]

Tungsten and tungsten carbide are two distinct substances with unique applications and properties. Tungsten is typically used in lighting equipment, electronic devices, and as electrodes and leads in semiconductor devices. Tungsten carbide, on the other hand, is employed in tools, molds, and wear-resistant parts. Despite their close chemical relationship, they differ fundamentally in hardness, applications, and chemical composition.

Chemical Properties of Tungsten

Tungsten is a pure metal, often used in industry in the form of tungsten powder, which is characterized by high density and a high melting point.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Chemical Properties of Tungsten Carbide

Tungsten carbide (WC) is a compound of tungsten and carbon, produced at high temperatures of 1400-1600°C from tungsten powder, carbon, and hydrogen. This process imparts tungsten carbide with its unique hardness and wear resistance.

Hardness and Material Properties

Tungsten

Tungsten, the 74th element on the periodic table, is renowned for its extremely high melting point (3370°C) and ultra-high density (19.25 g/cm³). In its pure state, tungsten is very expensive, and its purity significantly affects its physical properties. Impure tungsten is much less ductile and can be brittle even at room temperature.

Tungsten Carbide

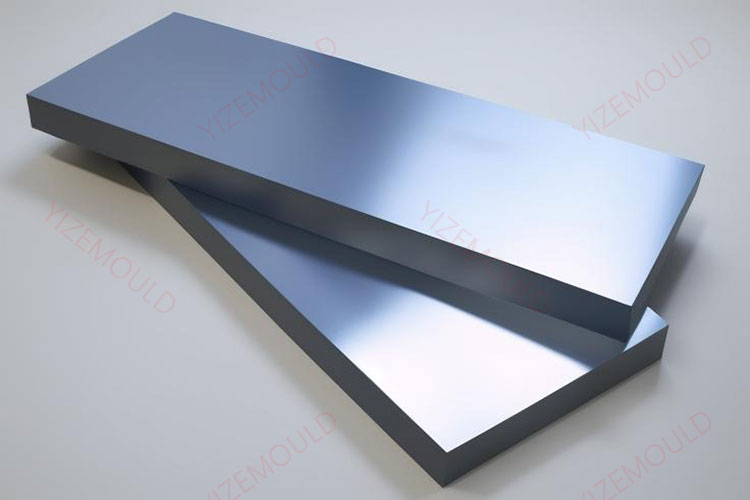

Tungsten carbide, a compound of tungsten, boasts 2-3 times the stiffness of steel and the highest compressive strength among all known alloys. Its hardness is nearly comparable to that of diamond, making it one of the hardest materials known. Additionally, tungsten carbide exhibits remarkable resistance to deformation and maintains stability under extreme high and low temperatures.

Applications

Applications of Tungsten

Tungsten is used in high-temperature filaments, electron tubes, electrodes and leads for electronic and semiconductor devices, special alloys, and aerospace materials. Historically, tungsten was widely used in incandescent lamp filaments, and it still plays a crucial role in halogen and fluorescent lamps today. In electron tubes, tungsten serves as cathode material, contributing its high emission current and long service life.

Applications of Tungsten Carbide

Tungsten carbide is valued in the manufacture of hard alloys, tool steels, and ceramics. Its superior hardness and wear resistance make it ideal for use in metal cutting tools, drills, and bits. Additionally, tungsten carbide is used as a coating material and in electrical contacts.