Titanium carbide

TiC-based cemented carbide is mainly used as a cutting tool. It can not only meet the precision machining of steel, but also perform semi-precision machining, rough machining, and intermittent cutting […]

TiC-based cemented carbide is mainly used as a cutting tool. It can not only meet the precision machining of steel, but also perform semi-precision machining, rough machining, and intermittent cutting of steel and tough cast iron.

The manufacturing process of TiC-based cemented carbide adopts liquid phase sintering: TiC powder and Ni (Co) powder are placed in a ball mill in a certain proportion for wet grinding, and then the slurry is dried and mixed with a lubricant, and formed under a pressure of 150 MPa to 200 MPa. The green compact is pre-sintered at 760 MPa to 870°C, and finally vacuum sintered at 1250°C to 1900°C. Factors affecting the performance of TiC-based alloys include: Ni content, Mo2C content, carbide phase, alloy carbon content, carbide grain size, structural defects, and their sizes.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

- Impact of Ni content. In TiC-Ni-Mo alloys, when the Mo content in the alloy is constant, the flexural strength of the alloy increases with the increase of Ni content, while the hardness decreases.

- Impact of Mo content. When the Ni content in the TiC-Ni-Mo alloy is kept constant, the flexural strength of the alloy increases with the increase of Mo content. This is because Mo improves the wettability of the binder phase to TiC.

- Impact of carbides. TaC, NbC, WC, and other carbides have many similarities in their effects on the performance of TiC-based alloys. They are all inhibitors of grain growth, which reduces the wettability of the binder phase to TiC. Therefore, their addition not only has a negligible effect on the hardness improvement of the alloy but also significantly reduces the strength of the alloy. The addition of WC increases the strength of the alloy while slightly reducing the hardness. This is because the addition of WC improves the wettability of the binder phase to titanium carbide, thereby increasing the strength of the alloy, while the coarsening of carbide grains leads to a decrease in hardness.

- Impact of carbide grain size. The finer the TiC particles, the better the strength.

- Impact of structural defects in TiC-based alloys. TiC-based alloys are prone to brittle fracture caused by internal structural defects (such as voids, Ni pools, carbonitride aggregates), so the fracture strength of the alloy is affected by the position and size of the defects. The addition of Mo2C can refine the structure or increase the amount of liquid phase during sintering, making it difficult to form micropores. At the same time, the formation of coarse carbides is suppressed by the encapsulation structure, resulting in improved strength of the alloy.

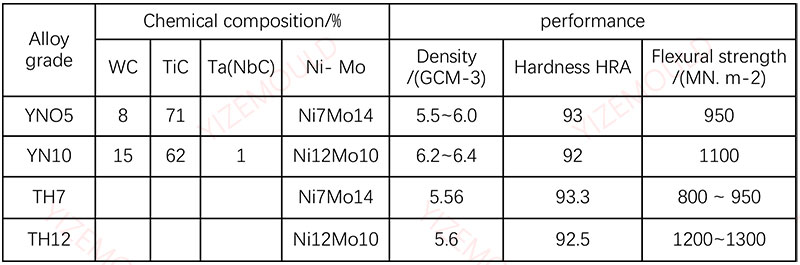

Performance table of TiC-based carbide produced in China.