The Applications of Tungsten Carbide

Tungsten carbide, as a high-performance hard alloy material, occupies an important position in modern industry due to its high hardness, wear resistance, corrosion resistance, and other characteristics. This article delves […]

Tungsten carbide, as a high-performance hard alloy material, occupies an important position in modern industry due to its high hardness, wear resistance, corrosion resistance, and other characteristics. This article delves into the applications of tungsten carbide across multiple fields.

In the cutting tool sector, tungsten carbide tools, with their high hardness and wear resistance, are the preferred choice for manufacturing high-precision, high-load cutting tools. They are widely used in industries such as automobile manufacturing and aerospace, significantly enhancing processing efficiency and tool lifespan.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

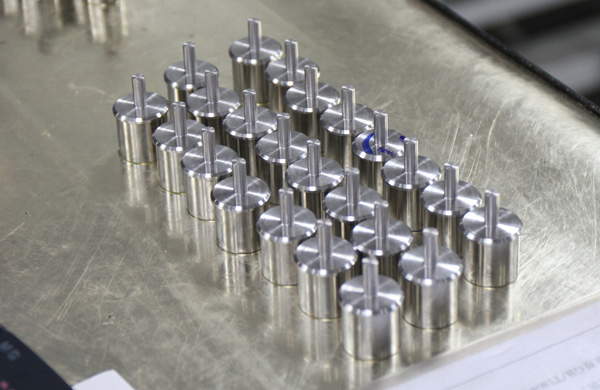

In mold manufacturing, tungsten carbide molds, characterized by their high precision and wear resistance, meet the molding needs of materials like plastics and rubber. They particularly excel in the manufacturing of automotive components.

In the mining and drilling sectors, tungsten carbide tools, with their strong wear resistance, effectively resist rock abrasion, enhancing drilling efficiency and safety.

Furthermore, tungsten carbide is widely applied in wear-resistant parts, metal dies, as well as in aerospace, electronics, medical, and other fields. Its exceptional properties contribute to improved production efficiency and product quality.

With technological advancements and industrial development, the application fields of tungsten carbide will continue to expand, injecting more vitality and momentum into modern industry and driving its prosperity and growth.