Surface smoothness in wire edm machining

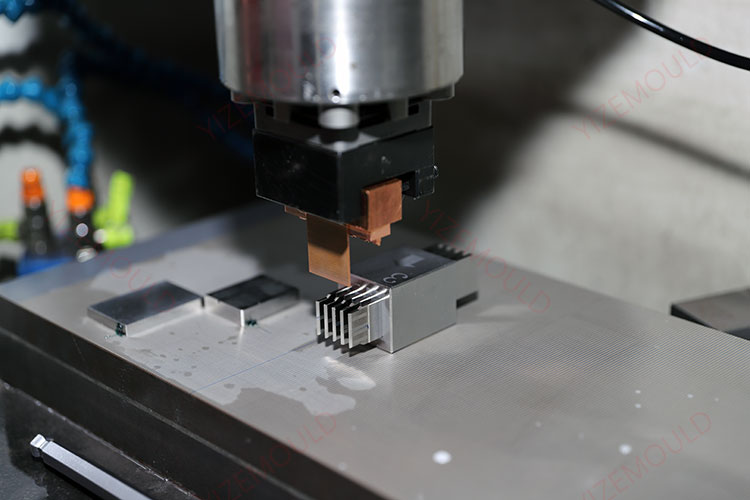

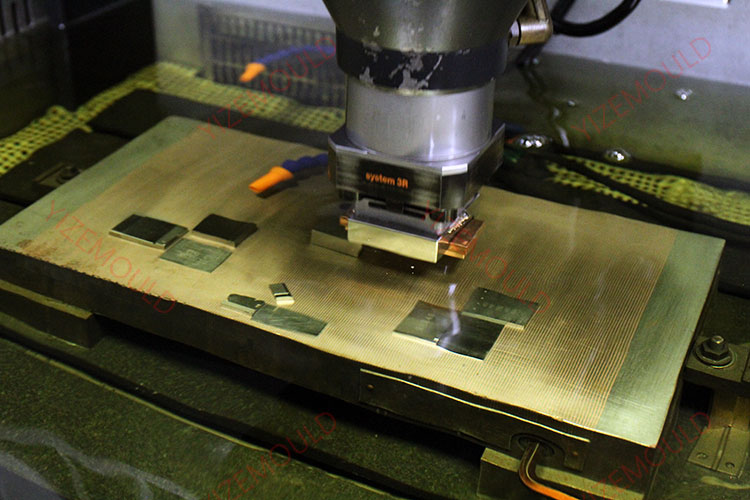

Wire EDM machining, similar to traditional electrical discharge machining (EDM), relies on discharges to melt the material for processing, resulting in a textured surface similar to orange peel. The flat […]

Wire EDM machining, similar to traditional electrical discharge machining (EDM), relies on discharges to melt the material for processing, resulting in a textured surface similar to orange peel. The flat surface used for smoothness measurement is perpendicular to the thickness of the workpiece, parallel to the feed direction of the worktable.

The surface smoothness in wire EDM machining exhibits a tendency to increase with the increase in current, similar to the processing speed. This tendency is particularly significant at a higher capacitance of 0.25 microfarads. Additionally, the surface smoothness varies with different capacitance levels, with better smoothness achieved in cases of lower capacitance. Therefore, when a high surface smoothness is required, machining should be performed with lower capacitance.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

In machining with higher capacitance, the surface smoothness varies with different workpiece thicknesses, improving as the thickness increases. However, when the capacitance is 0.025 microfarads or smaller, the effect of workpiece thickness on surface smoothness becomes less significant.

The surface smoothness varies with different open-circuit voltages, and satisfactory surface quality can be achieved only at lower open-circuit voltages.

Carbide exhibits better surface smoothness compared to alloy tool steel. At a capacitance of 0.25 microfarads, the surface smoothness of alloy tool steel is around 20-30 μRmax, while that of carbide is around 10-15 μRmax. Generally, carbide demonstrates better surface smoothness. When machining alloy tool steel using tungsten wire, the surface smoothness is around 16-22 μRmax. The surface smoothness obtained from copper wire machining at a capacitance of 0.05 microfarads is roughly similar to that of tungsten wire machining. Furthermore, wire EDM machining generally yields better surface smoothness compared to spark erosion machining.