Points for Attention When Using Tungsten Carbide Punch

A tungsten carbide punch is a component in a mold that directly contacts the material for cutting and pressure deformation. Therefore, the hardness of the punch is crucial, and tungsten […]

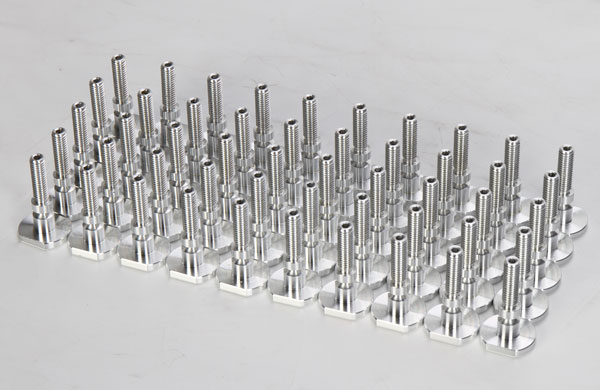

A tungsten carbide punch is a component in a mold that directly contacts the material for cutting and pressure deformation. Therefore, the hardness of the punch is crucial, and tungsten carbide material is often adopted to withstand high temperatures and materials with high hardness. So, what should we pay attention to when using a tungsten carbide punch?

Here are some points for attention when using a tungsten carbide punch:

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

When operating the tungsten carbide punch, strictly follow the machine’s instructions to avoid damage caused by improper operation. Additionally, be cautious about waterproofing and moisture protection, and promptly wipe off any water on the punch surface. Although tungsten carbide, the material of the punch, has strong corrosion resistance, it still requires careful protection to avoid unnecessary wear and tear. During routine maintenance, frequently check the punch’s lubricating oil and surface dirt, and clean it promptly to extend the punch’s service life and effectively exert its function.

If you want to extend the service life of the tungsten carbide punch, operators need to be more attentive during the processing and usage. Applying some lubricants can reduce external friction, thereby reducing wear to a certain extent. Therefore, for some high-end punches, lubricants are applied before use for protection. Furthermore, as the punch is constantly in contact with materials, leading to wear and tear, the cleaning and maintenance of the punch are particularly important.