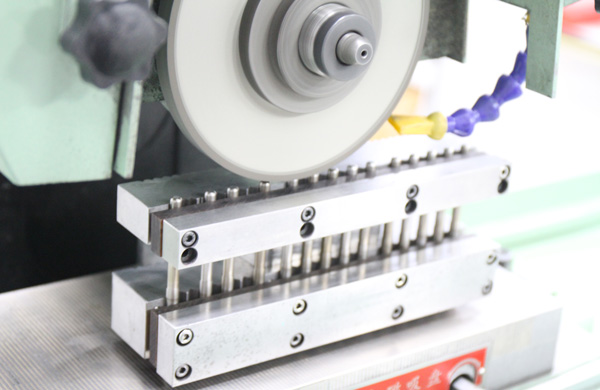

Key Points of Tungsten Carbide Plate Grinding Process

Tungsten carbide plates, as a leading hard alloy material, are widely used in various fields. However, their high hardness poses challenges for processing, especially during the grinding process. Mastering the […]

Tungsten carbide plates, as a leading hard alloy material, are widely used in various fields. However, their high hardness poses challenges for processing, especially during the grinding process. Mastering the key points of grinding is crucial for improving product quality and reducing production costs.

In the selection of grinding equipment and tools, we need to comprehensively consider the precision, stability, and processing efficiency of the equipment, choosing professional grinding equipment and suitable tools to ensure stable and consistent processing, improve product processing precision, and extend tool life.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Control of parameters during the grinding process is equally critical. The setting of grinding pressure and speed should be scientific and reasonable to avoid issues such as surface cracks, damage, and heat accumulation on the plates. At the same time, the choice of grinding fluid is also essential, as it should have good lubrication and cooling effects to improve grinding efficiency.

The flatness and smoothness of the grinding surface are important requirements for the grinding of tungsten carbide plates. We should adopt appropriate grinding processes and tools, and strictly control the temperature during grinding to maintain the high quality of the grinding surface.

In addition, optimizing the grinding process and workflow, strengthening equipment maintenance and care, and improving the skill level of operators are also key measures to enhance the efficiency and quality of grinding.

Looking ahead, with advancements in technology and innovations in processes, the tungsten carbide plate grinding technology will embrace broader applications and development opportunities.