In-depth Analysis of the Practicality of Tungsten Carbide Dies

I. Introduction In the vast stage of metal processing and manufacturing, molds play a pivotal role, with their quality and performance directly affecting the precision, quality, and production efficiency of […]

I. Introduction

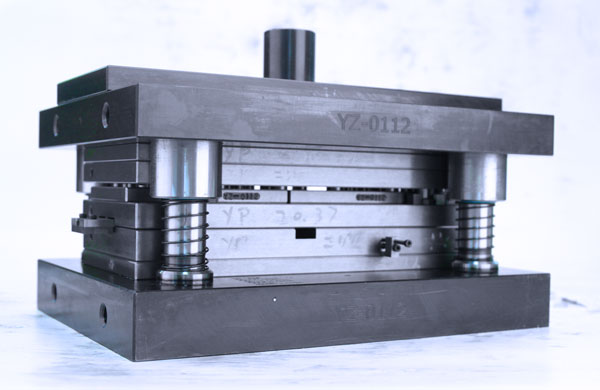

In the vast stage of metal processing and manufacturing, molds play a pivotal role, with their quality and performance directly affecting the precision, quality, and production efficiency of products. tungsten carbide dies, as outstanding mold materials, have shone brightly in numerous industrial fields thanks to their excellent hardness, wear resistance, corrosion resistance, and good toughness. This article will comprehensively analyze the practical charm of tungsten carbide dies from the dimensions of their material properties, application fields, service life, processing efficiency, and maintenance costs.

II. Material Properties of Tungsten Carbide Dies: Unbreakable and Extraordinarily Durable

High Hardness and Wear Resistance: The hardness of tungsten carbide dies easily surpasses 90HRA, far exceeding that of ordinary steels, making them stable in high-pressure, high-wear environments. Their wear resistance is also outstanding, maintaining a low wear rate over long-term use and significantly extending the life of the molds.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Excellent Heat Resistance: Faced with high-temperature challenges, tungsten carbide dies exhibit extraordinary heat resistance, with their hardness and rigidity remaining unchanged, making them an ideal choice for manufacturing high-temperature alloys, ceramics, and other materials.

Good Corrosion Resistance: Tungsten carbide dies can resist the corrosion of corrosive media, such as acids and alkalis, ensuring stable performance in harsh environments.

Outstanding Toughness: Tungsten carbide dies not only have high hardness but also excellent toughness, are able to withstand impacts and vibrations, effectively prevent fractures, and enhance the safety and reliability of the molds.

III. Application Fields of Tungsten Carbide Dies: Wide Coverage, Showing Their Sharp Edge

Tungsten carbide dies, with their excellent performance, have shone brightly in multiple fields:

Electronic and Electrical Field: In the manufacturing of mobile phone batteries and electronic product casings, tungsten carbide dies have won favor with their high precision and wear resistance.

Medical Device Field: The manufacturing of surgical instruments, medical needles, and other medical devices cannot do without the precision and reliability of tungsten carbide dies.

Home Appliance Manufacturing Field: Due to their high hardness, wear resistance, and high precision, tungsten carbide dies have become the first choice in the production of refrigerator compressors, washing machine motors, and other home appliances.

Cutting Tool Manufacturing: The addition of tungsten carbide dies in the manufacturing of cutting tools, such as cemented carbide cutters, has significantly improved the cutting efficiency and life of the tools.

IV. Service Life of tungsten carbide dies: Long-lasting and Value-prominent

The service life of tungsten carbide dies far exceeds that of ordinary steel molds, with a difference of several to tens of times, thanks to their high hardness, wear resistance, and corrosion resistance. In high-pressure, harsh environments, tungsten carbide dies remain as solid as a rock, with a small expansion coefficient and low risk of deformation, further extending their service life.

V. Processing Efficiency of Tungsten Carbide Dies: Efficient Cutting, Stable as Always

The high hardness and wear resistance of tungsten carbide dies ensure high cutting speeds and precision during processing. Their excellent heat resistance allows the molds to work stably in high-temperature environments, significantly improving processing efficiency. At the same time, their toughness reduces downtime and maintenance costs during processing.

VI. Maintenance Costs of Tungsten Carbide Dies: Economically Efficient, a Long-term Choice

Although the initial investment for tungsten carbide dies is higher, the economic benefits brought by their long service life and high processing efficiency far exceed the costs. The low wear rate reduces the frequency of mold replacements and maintenance costs. Their corrosion resistance and heat resistance also reduce the risk of replacement due to corrosion and high-temperature damage, making tungsten carbide dies an economically efficient long-term choice.

VII. Conclusion: Tungsten Carbide Dies, a Practical Choice with a Promising Future

In summary, tungsten carbide dies have demonstrated their unparalleled practicality with their excellent material properties, wide range of application fields, long service life, high processing efficiency, and economical maintenance costs. With the蓬勃 development of the manufacturing industry, the application prospects for tungsten carbide dies will become even broader, becoming an important force driving industrial progress.