Exploring the Significant Advantages of Overpressure Sintering for Tungsten Carbide Cylinders

In the realm of tungsten carbide products, while mass-produced items like plates and rods enjoy widespread popularity, their technological advancements are often overlooked by some manufacturers, leaving room for improvement […]

In the realm of tungsten carbide products, while mass-produced items like plates and rods enjoy widespread popularity, their technological advancements are often overlooked by some manufacturers, leaving room for improvement in manufacturing techniques.

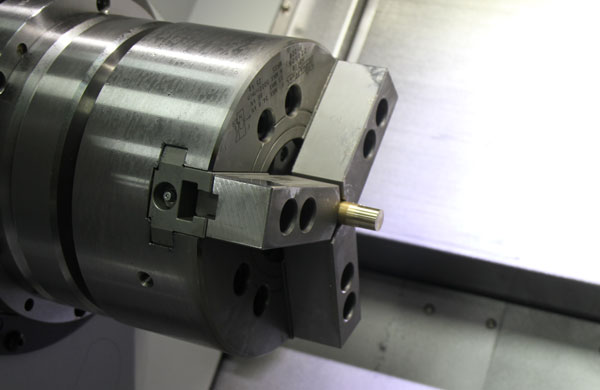

Tungsten carbide rods, primarily used in tools, punching dies, and wear-resistant components, feature a relatively limited range of specifications, with variations mainly in outer diameter. Their lengths can be easily adjusted through cutting, greatly facilitating inventory management for manufacturers and distributors. However, tungsten carbide cylinders, which mostly involve non-standard specifications and are often produced on a made-to-order basis, present a different challenge. Due to the immediate production and use, internal stresses within the material can accumulate significantly. Without the application of overpressure sintering, these cylinders are prone to cracking during subsequent wire cutting or other processing steps, severely compromising product quality and production efficiency.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

It is worth noting that tungsten carbide rods and plates, owing to their mass production nature, can undergo precise parameter control through trial pressing and sintering during the manufacturing process, ensuring stable production and consistent quality. Conversely, tungsten carbide cylinders, as non-standard products, often receive orders in limited quantities, sometimes just a single unit. Adhering to traditional trial pressing and sintering procedures in such cases would substantially increase production costs, making it unacceptable to most customers. Therefore, the adoption of overpressure sintering technology has become crucial for enhancing the quality of tungsten carbide cylinders and meeting customers’ personalized needs. This optimized process not only effectively addresses internal stress issues but also ensures that the material properties meet or exceed customer expectations, fostering a mutually beneficial situation.

In conclusion, the application of overpressure sintering in the production of tungsten carbide cylinders represents not only a technological advancement but also a precise response to the market’s diverse demands.