Precautions for design of carbide blanking die

The dies manufactured using carbide for either the punch or the die, or dies where both the punch and the die are made of carbide, are referred to as carbide […]

The dies manufactured using carbide for either the punch or the die, or dies where both the punch and the die are made of carbide, are referred to as carbide dies. Both the punch and the die can be made entirely of carbide or have a piece of carbide attached or embedded onto a steel part as the working section for blanking. A layer of carbide can also be sprayed onto the cutting edge of a steel mold. Due to the high hardness and wear resistance of carbide, the lifespan of carbide dies is several times to tens of times longer than that of general steel dies. However, due to the brittleness of carbide and the impact loads during the blanking process, tough carbides are often used for mold applications.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Both the punch and the die are made of carbide, and the structural form of carbide blanking dies is similar to that of general dies, but it also has its own characteristics. The following issues should be considered during the design process:

- carbide has a lower capacity to withstand bending loads. When arranging the layout, attention should be paid to the position of the first cutting edge to prevent half of the contour or half of the hole from being cut, which would result in unilateral stress on the punch.

- The burr height is larger compared to general blanking, and it should be larger than the material thickness to prevent the burr from being squeezed into the die, which could damage the mold.

- The blanking clearance should be appropriately increased.

- The rigidity of the mold frame should be sufficient, and the components on the mold should be compatible with the high-life die. For example, both the upper and lower mold bases are made of steel and have a thickness 1.5 times that of general dies. Locating pins and guide plates are made of 45 steel and undergo quenching treatment. The back of the punch and die is reinforced with thicker backing plates that are also quenched.

- The guiding accuracy and service life of the mold frame should be high to match the high-life die. Rolling guide mold frames and interchangeable guide pillars are commonly used, with four guide pillars often used for large or complex workpieces. Floating-type mold holders are commonly used to overcome the influence of press errors on guiding accuracy.

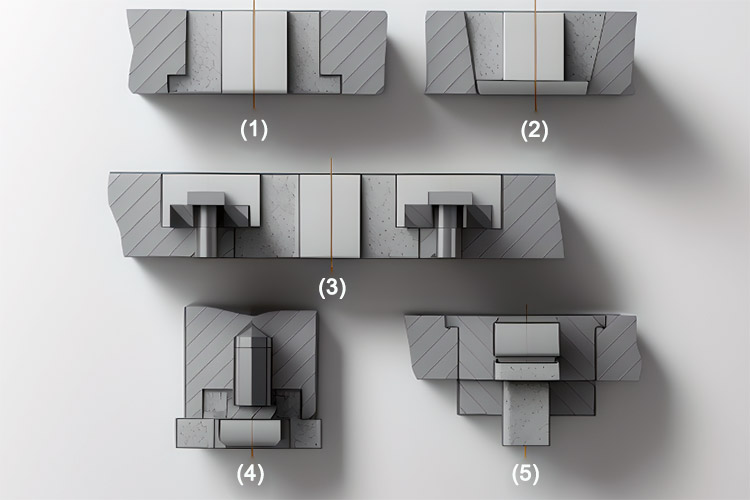

- Both the punch and the die can be made entirely of carbide or inlaid with carbide. carbide can also be attached or welded onto steel parts.

- If a spring-loaded unloading plate is used for unloading, precautions should be taken to prevent the unloading plate from impacting the carbide die, causing uneven stress and resulting in cracks. In this case, the height of the lower part of the unloading plate should be 0.05 to 0.01mm lower than the height of the guide plate (the height of the material thickness). The unloading plate only serves the purpose of unloading without applying pressure. If it is necessary to perform compression blanking on thin materials, guide pillars can be added between the unloading plate and the fixed plate of the die or punch to evenly compress the workpiece.