Comprehensive Analysis of Tungsten Carbide Parts: Characteristics, Types, Applications, and Future Trends

Tungsten carbide, a high-performance cemented carbide material, occupies a pivotal position in the industrial manufacturing sector. Its specific application form, tungsten carbide parts, are widely popular due to their excellent […]

Tungsten carbide, a high-performance cemented carbide material, occupies a pivotal position in the industrial manufacturing sector. Its specific application form, tungsten carbide parts, are widely popular due to their excellent wear resistance, high hardness, and high thermal stability.

The characteristics of tungsten carbide parts are remarkable: their high hardness allows them to remain stable in complex environments; their high wear resistance ensures stability in shape and size under long-term working conditions; their high thermal stability maintains performance even at high temperatures; and their good corrosion resistance allows them to maintain stable performance in harsh environments.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

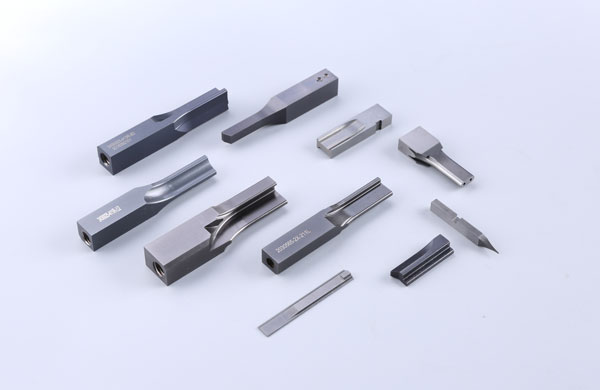

Tungsten carbide parts come in a variety of types and have wide applications. Cutting tools such as milling cutters and drills play an important role in metal processing; mold components such as punches and dies improve the precision and durability of molds; aerospace parts such as engine blades and turbine disks meet the high-performance requirements under extreme conditions. In addition, they are widely used in mining, oil drilling, and other fields.

The production process of tungsten carbide parts is rigorous. From raw material preparation and powder mixing to pressing and sintering, and finally to post-processing, each step requires strict control to ensure the quality and precision of the parts.

Looking ahead, tungsten carbide parts will exhibit trends towards customization, environmental friendliness and energy efficiency, high performance, and intelligence. Customized production will meet individual needs; environmental friendliness and energy efficiency will become important considerations in production; high performance will adapt to harsher working environments; and intelligence will enable automated production and quality control.

Tungsten carbide parts, as a shining star in the industrial manufacturing sector, will surely radiate even more brilliantly in the future.