Carbide: The Solid Foundation of Modern Industry

Carbide, a high-performance metal composite material, has become an indispensable key element in modern industrial fields. With its excellent physical and chemical properties, it shines in manufacturing, mechanical processing, aerospace, […]

Carbide, a high-performance metal composite material, has become an indispensable key element in modern industrial fields. With its excellent physical and chemical properties, it shines in manufacturing, mechanical processing, aerospace, and many other sectors. In the following, this article will delve into the mysteries of carbide, providing a comprehensive understanding of its characteristics and advantages through detailed introductions to its definition, composition, performance features, production process, classification, and application fields.

I. The Precise Definition of Carbide

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Carbide, also known as hardmetal or cermet, is an alloy material produced through powder metallurgy by skillfully fusing refractory metal hard compounds with binder metals. It cleverly combines the dual advantages of metals and ceramics, exhibiting a series of outstanding properties such as high hardness, wear resistance, high strength, good toughness, heat resistance, and corrosion resistance.

II. Unveiling the Composition of Carbide

In the composition of carbide, hard phases such as tungsten carbide (WC), titanium carbide (TiC), and tantalum carbide (TaC) dominate, while binder phases like cobalt (Co), nickel (Ni), and iron (Fe) play a crucial role in connecting them. Among them, tungsten carbide, as the core component, often accounts for more than half of the alloy’s total content, ensuring the alloy’s hardness and durability.

III. Highlighting the Performance Features of Carbide

- High Hardness: Carbide’s hardness is unparalleled, typically ranging between 86~93HRA, equivalent to 69~81HRC, making it exhibit excellent wear resistance in cutting and grinding processes.

- High Strength: Even when faced with the severe challenges of heavy-duty and high-speed cutting, carbide can maintain stable performance due to its high strength characteristics.

- Excellent Heat Resistance: In high-temperature environments of up to 900~1000℃, carbide can still maintain high hardness and strength, with a hot hardness of up to 60HRC, ensuring outstanding cutting and grinding performance at high temperatures.

- Outstanding Corrosion Resistance: Whether in acidic or alkaline corrosive media, carbide can easily cope and maintain its stability, making it widely popular in the chemical and petroleum industries.

- Good Red Hardness: Even in high-temperature environments, carbide can maintain high hardness and rigidity, without easy softening or deformation, ensuring precise and efficient cutting and grinding.

IV. Exploring the Production Process of Carbide

The production process of carbide is rigorous and meticulous, involving multiple steps such as material preparation, powder mixing, molding, sintering, and post-processing. From the careful selection and proportioning of raw materials to the uniform mixing of powders, and then to the dense molding and high-temperature sintering of the blanks, each step is crucial, jointly contributing to the hardness and durability of carbide.

V. The Diverse Classification of Carbide

Carbide can be classified in various ways, either by composition into tungsten-titanium series, tungsten-molybdenum series, tungsten-titanium-cobalt series, and tungsten-titanium-steel series to meet different performance requirements, or by application into cutting tool, abrasive, impact, and electronic packaging grades to suit application scenarios in various fields.

VI. The Wide Range of Applications for Carbide

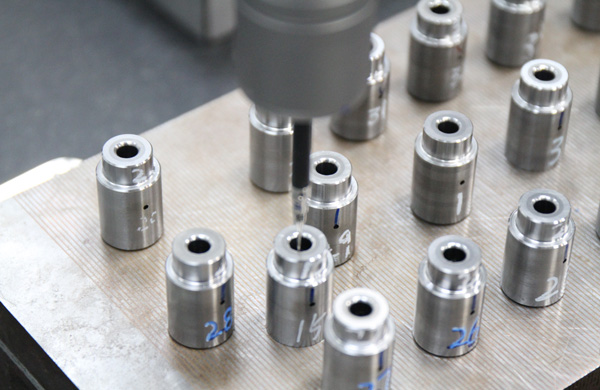

Carbide, with its excellent performance, shines in cutting and processing, petroleum exploration and extraction, metal processing, welding, silicon carbide wafer manufacturing, and many other fields. Whether it’s manufacturing cutting tools, drills, saw blades, or coping with extreme environments in petroleum exploration and extraction, carbide can provide strong support for the development of various industries with its toughness and durability.

VII. Conclusion

In summary, carbide, as the solid foundation of modern industry, plays an important role in various fields with its unique performance advantages. With the advancement of technology and the development of industry, the application fields of carbide will continue to expand, contributing more to the progress of human civilization. Let us look forward together to this magical material creating more miracles in the future!

Related Posts

- Guide to Identifying Tungsten Carbide Plate Quality: A Comprehensive Analysis

- Tungsten Carbide Materials: Characteristics, Advantages, and Comprehensive Applications Analysis

- An In-depth Analysis of Tungsten Carbide’s Corrosion Resistance

- Comprehensive Guide to Tungsten Steel Mold Installation: Details Make the Difference