Basic Guide to Tungsten Carbide Pin Gauges

Among various industrial measurement tools, Tungsten Carbide Pin Gauges stand out due to their exceptional hardness, wear resistance, strength, toughness, heat resistance, and corrosion resistance. Notably, even at temperatures of […]

Among various industrial measurement tools, Tungsten Carbide Pin Gauges stand out due to their exceptional hardness, wear resistance, strength, toughness, heat resistance, and corrosion resistance. Notably, even at temperatures of 500℃, their hardness and wear resistance remain virtually unchanged, and they maintain considerable hardness even at 1000℃. This makes Tungsten Carbide Pin Gauges ideal for a wide range of processing needs and compatible with numerous mechanical devices, earning them the title of versatile precision pins.

With the growing market demand, the variety of Tungsten Carbide Pin Gauges has increased, but so has the quality disparity. To ensure the purchase of high-quality products and avoid falling prey to unscrupulous vendors, it is crucial to have a basic understanding of Tungsten Carbide Pin Gauges.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Key Selection Criteria for Pin Gauges

- Material Selection: Materials that have not undergone deep cryogenic treatment have a higher expansion coefficient, leading to size deviations over time and with temperature changes.

- Hardness Index: Hardness directly impacts durability, and even materials with the same hardness can exhibit different wear resistance properties.

- Cylindricity Accuracy: The entire length of the pin gauge’s outer diameter must be within the specified tolerance; any deviation at the ends renders it unacceptable.

- True Roundness: Typically, this should be within half of the tolerance. For example, a +/-1μm roundness requirement should be maintained within 1μm, and so on.

- Surface Finish: A rough surface, resembling mountain peaks, has small contact areas and is prone to wear, affecting accuracy. A high surface finish, on the other hand, means larger contact areas and greater wear resistance, with high-quality pin gauges often achieving a mirror-like finish.

- Precision Standard: As the core indicator, this varies among manufacturers. Our Tungsten Carbide Pin Gauges, made from SKD-11 material and subjected to vacuum heat treatment and deep cryogenic treatment, achieve a maximum tolerance of +/-0.3μm, a true roundness of 0.15μm, a cylindricity of 0.3μm, and a surface finish of RA 0.05 (mirror-like), with performance indicators closely rivaling imported products.

Wise Material Choices for Pin Gauges

- Stainless Steel Pin Gauges: Suitable for low-volume use or complete set purchases for non-standard hole measurement, known for their cost-effectiveness.

- Tungsten Carbide Pin Gauges: Ideal for large-volume measurement of both non-standard and standard internal holes, distinguished by their wear resistance, reducing replacement frequency and procurement workload.

- Ceramic Pin Gauges: Suitable for non-magnetic environments, with wear resistance similar to Tungsten Carbide and easy storage.

Manufacturing Process of Tungsten Carbide Pin Gauges

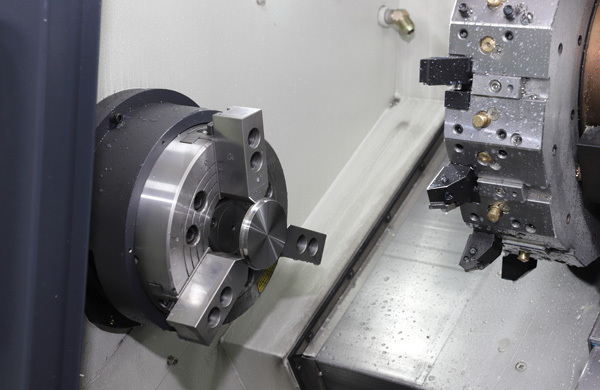

Tungsten Carbide Pin Gauges originate from high-quality Tungsten Carbide material, which is already a leader in the field of cutting and pin tools, widely used in turning tools, milling cutters, and more. Furthermore, Tungsten Carbide (hardmetal) is the preferred material for manufacturing rock drilling tools, mining tools, drilling tools, measuring instruments, wear-resistant parts, metal molds, cylinder linings, precision bearings, and nozzles. The manufacturing process of Tungsten Carbide Pin Gauges involves powder pressing, high-temperature sintering, and subsequent precision machining and adjustment, each step critical to ensuring the final product meets high standards.

By delving into this knowledge, you will navigate the Tungsten Carbide Pin Gauge market with confidence, selecting the highest quality products tailored to your needs.