An Overview of the Product Advantages of Tungsten Steel Pin Gauge Company

Tungsten Steel Pin Gauge Company, as an integrated enterprise specializing in research, development, production, and sales, focuses on the deep processing of cemented carbide products, particularly excelling in the manufacture […]

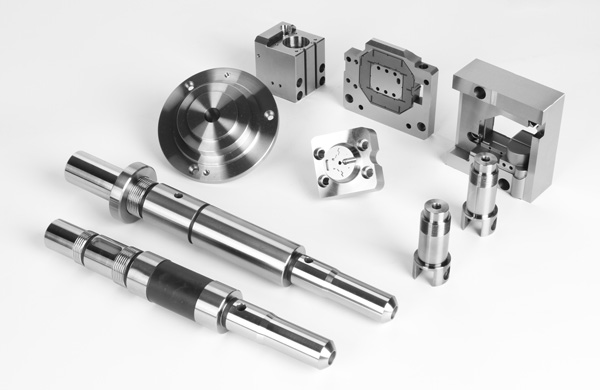

Tungsten Steel Pin Gauge Company, as an integrated enterprise specializing in research, development, production, and sales, focuses on the deep processing of cemented carbide products, particularly excelling in the manufacture of various types of tungsten steel molds. Our product line encompasses high-quality cemented carbide items such as tungsten steel pin gauges, punches, and bushings, adhering to a service philosophy of “swift delivery, consistent quality, and welcoming small orders.”

Application Fields and Functional Features of Tungsten Steel Pin Gauges:

Tungsten steel pin gauges serve as indispensable tools for precise measurement of hole diameters, depths, and distances. They are widely utilized in fields such as electronic circuit boards, circuit board manufacturing, and precision mold development, ensuring standardized quality control in hole processing. Their unique go/no-go design further enhances the convenience and accuracy of inspections.

Our factory business: carbide parts, mold parts, medical injection molds, precision injection molds, teflon PFA injection molding, PFA tube fittings. email: [email protected],whatsapp:+8613302615729.

Product Customization and Technical Advantages:

With cemented carbide molds as our core offering, we provide a one-stop service from product measurement, mold design, to custom processing based on drawings or samples. We excel in tailoring non-standard specifications, including imperial measurements, with a standard tolerance of ±0.001MM and lengths up to 50MM. The hardness of our tungsten steel pin gauges is maintained at 88-90 HRA, ensuring exceptional strength and wear resistance.

Quality Control and Certification System:

Our company has obtained 3C certification and ISO9001:2000 quality management system certification. Each tungsten steel pin gauge undergoes a rigorous quality inspection process, utilizing internationally advanced laser detection equipment for precision verification. Production relies on M100CNC high-precision grinding machines and vacuum heat treatment techniques, ensuring superior product quality and packaging that meets international export standards. As a long-term partner of multiple large state-owned enterprises, we have accumulated extensive experience in the design and manufacture of cemented carbide molds, earning widespread praise from the market for our rapid response and high-quality services.

Related Posts

- The Unique Features of Tungsten Carbide Punch Design and Application

- 8 Key Dimensions to Evaluate Whether Your Tungsten Carbide Punch Manufacturer’s Service is Truly Comprehensive

- Basic Guide to Tungsten Carbide Pin Gauges

- Manufacturing Process and Performance Application of Tungsten Carbide Bushings